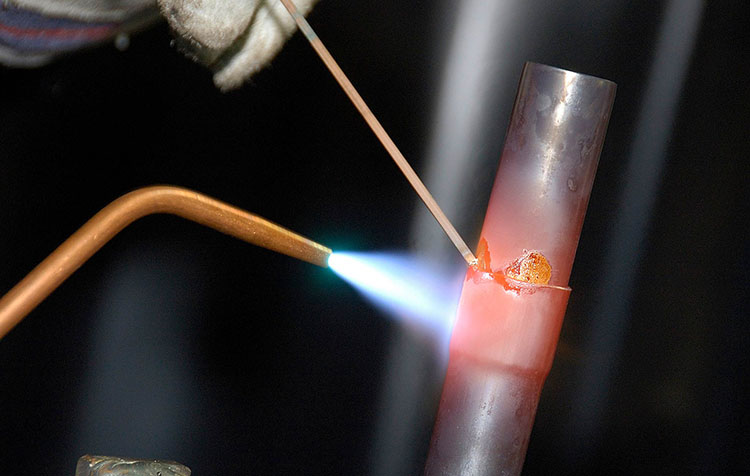

-

Mohloli oa matla oa brazing e ka ba mocheso oa lik'hemik'hale kapa matla a mocheso a sa tobang.E sebelisa tšepe e nang le ntlha e qhibilihang ka tlase ho ea thepa e lokelang ho chesetsoa e le solder.Ka mor'a ho futhumatsa, solder ea qhibiliha, 'me ketso ea capillary e sutumelletsa solder ka lekhalo pakeng tsa sebaka sa ho kopana ...Bala haholoanyane»

-

Lintlha tse kotsi tsa thepa ea ho cheselletsa (1) Ntho ea mantlha ea lipatlisiso tsa bohloeki ba mosebetsi oa ho cheseletsa ke fusion welding, 'me har'a bona, mathata a bohloeki ba mosebetsi oa ho tjheseletsa arc ke a maholo ka ho fetesisa,' me mathata a ho tjheseletsa arc ka metsing le ho cheseletsa ka electroslag ke a manyane.(2) Ntho e ka sehloohong e kotsi fa...Bala haholoanyane»

-

Welding e ka sebelisa mochini oa welding oa AC kapa oa DC.Ha o sebelisa mochini oa welding oa DC, ho na le khokahano e ntle le khokahanyo e khutlisetsang morao.Lintlha tse kang electrode e sebelisitsoeng, boemo ba thepa ea kaho le boleng ba ho cheselletsa li lokela ho nkoa.Ha ho bapisoa le phepelo ea motlakase ea AC, matla a DC ...Bala haholoanyane»

-

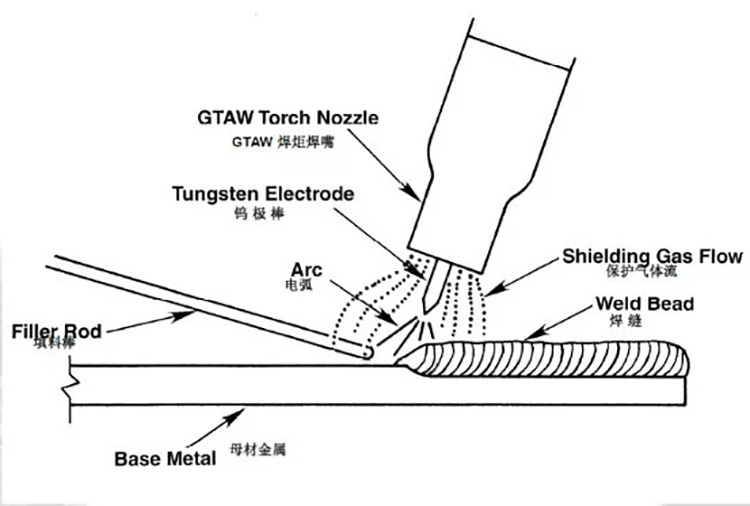

Hlooho e khubelu thoriated tungsten electrode (WT20) Hajoale electrode ea tungsten e tsitsitseng ka ho fetesisa le e sebelisoang haholo e sebelisoa haholo ho cheselletsa carbon steel, tšepe e sa hloekang, koporo ea silicon, koporo, boronse, titanium le lisebelisoa tse ling, empa e na le tšilafalo e nyane ea radioactive.Hlooho e bohlooho cerium tungst...Bala haholoanyane»

-

Argon tungsten arc welding e sebelisa argon e le khase e sireletsang ho futhumatsa le ho qhibilihisa thepa ea welding ka boeona (e boetse e qhibiliha ha tšepe ea ho tlatsa e kenngoa) ka arc e hlahisoang pakeng tsa electrode ea tungsten le 'mele oa weld, ebe e etsa welding. ea weld metal Way.Tungsten e ...Bala haholoanyane»

-

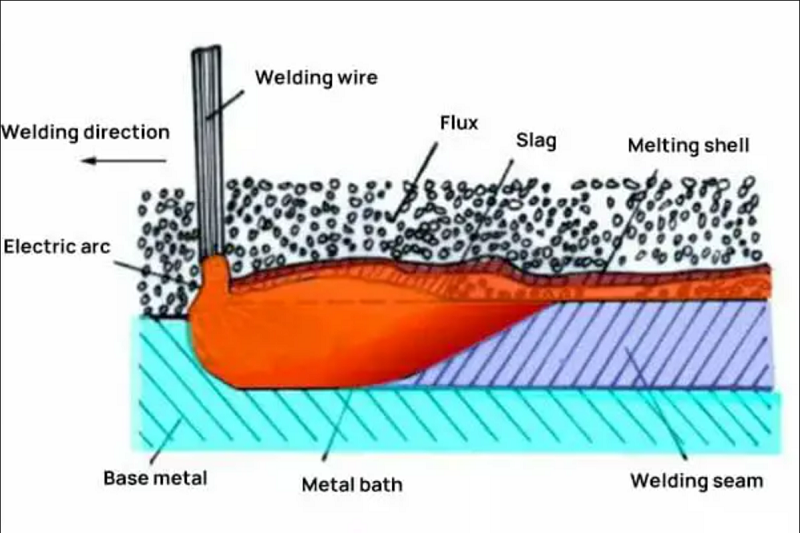

Flux-cored arc welding ke eng?Flux-cored wire arc welding ke mokhoa oa ho tjheseletsa o sebelisang arc pakeng tsa terata e nang le flux-cored le workpiece ho futhumatsa, 'me lebitso la eona la Senyesemane ke FCAW feela.Tlas'a ts'ebetso ea mocheso oa arc, tšepe ea welding le workpiece li kopantsoe ka ho qhibiliha, ho etsa letamo la weld, arc f ...Bala haholoanyane»

-

Ha ho chesetsoa tšepe e sa hloekang, ts'ebetso ea electrode e tlameha ho lumellana le morero oa tšepe e sa hloekang.Electrode ea tšepe e sa hloekang e tlameha ho khethoa ho ea ka tšepe ea motheo le maemo a sebetsang (ho kenyeletsoa mocheso oa ho sebetsa, mokhoa oa ho ikopanya, joalo-joalo).Mefuta e mene ea tšepe e sa hloekang hape ...Bala haholoanyane»

-

FLUX- Flux ke sesebelisoa sa ho cheselletsa granular.Nakong ea welding, e ka qhibiliha ho etsa slag le khase, e phethang karolo e sireletsang le ea metallurgic holim'a letamo le qhibilihisitsoeng.Constituent Flux e entsoe ka 'mabole, quartz, fluorite le ores tse ling le titanium dioxide, selulose le tse ling ...Bala haholoanyane»

-

Welding ke ts'ebetso eo ho eona lisebelisoa tsa li-workpieces tse lokelang ho chesetsoa (tse tšoanang kapa tse fapaneng) li kopantsoe ka ho futhumatsa kapa khatello kapa ka bobeli, le ka kapa ntle le lisebelisoa tsa ho tlatsa, e le hore lisebelisoa tsa li-workpieces li hokahane lipakeng tsa liathomo ho theha. kgokelo.Joale lintlha tsa bohlokoa ke life...Bala haholoanyane»

-

TIG 1. Kopo : TIG welding (tungsten argon arc welding) ke mokhoa oa ho cheseletsa oo Ar e hloekileng e sebelisoang e le khase e sireletsang le li-electrode tsa tungsten li sebelisoa e le li-electrode.TIG wire welding e fanoa ka likhoele tse otlolohileng tsa bolelele bo itseng (hangata lm).Welding ea arc e sirelelitsoeng ka khase e inert e sebelisa...Bala haholoanyane»