Mohloli oa matla oa brazing e ka ba mocheso oa lik'hemik'hale kapa matla a mocheso a sa tobang.E sebelisa tšepe e nang le ntlha e qhibilihang ka tlase ho ea thepa e lokelang ho chesetsoa e le solder.Ka mor'a ho futhumatsa, solder e qhibiliha, 'me ketso ea capillary e sutumelletsa solder ka lekhalo pakeng tsa libaka tsa ho kopana tsa lenonyeletso ho kolobisa holim'a tšepe e lokelang ho kenngoa e le hore karolo ea mokelikeli le mohato o tiileng o arohane.Ho kena-kenana pakeng tsa mekhahlelo ho theha lenonyeletso le nang le brazed.Ka hona, brazing ke mokhoa o tiileng-mohato le oa metsi-mohato oa welding.

1. Litšobotsi le tšebeliso ea brazing

Brazing e sebelisa motsoako o nang le ntlha e qhibilihang ka tlase ho ea tšepe ea motheo e le solder.Ha e futhumala, solder e qhibiliha ebe e tlatsa 'me e sala e le ka har'a lekhalo le kopantsoeng ka ho koloba le khato ea capillary, ha tšepe ea motheo e le boemong bo tiileng, e itšetlehile ka solder ea mokelikeli le motheo o tiileng oa Interdiffusion pakeng tsa thepa e etsa lenonyeletso la brazed.Brazing e na le phello e fokolang ho thepa ea 'mele le ea lik'hemik'hale ea tšepe ea motheo, khatello e fokolang ea welding le deformation, e ka hlahisa litšepe tse sa tšoaneng tse nang le phapang e kholo ea thepa, e ka tlatsa li-welds tse ngata ka nako e le' ngoe, ponahalo ea lenonyeletso e ntle ebile e makhethe, thepa e bonolo, le letsete la tlhahiso e nyenyane.Leha ho le joalo, lenonyeletso la brazed le na le matla a fokolang le ho hanyetsa mocheso o futsanehileng.

Likopo: Lisebelisoa tsa ho itšeha tsa Carbide, likotoana tsa ho phunya, liforeimi tsa libaesekele, licheso tsa mocheso, li-conduits le lijana tse fapaneng, joalo-joalo;ha ho etsoa li-waveguides tsa microwave, li-tubes tsa elektronike le lisebelisoa tsa elektroniki tsa vacuum, brazing ke eona feela mokhoa o ka khonehang oa ho hokahanya.

2.Brazing tšepe le flux

Brazing filler metal ke tšepe e tlatsang e etsang hlooho ea brazing, 'me boleng ba hlooho ea brazing bo itšetlehile ka tšepe ea brazing ho isa tekanyong e kholo.Tšepe ea ho tlatsa e lokela ho ba le sebaka se loketseng sa ho qhibiliha, ho koloba hantle le bokhoni ba ho baka, e ka aroloa ka tšepe ea motheo, 'me e lokela ho ba le thepa e itseng ea mochine le thepa ea' mele le ea lik'hemik'hale ho finyella litlhoko tsa ts'ebetso ea motsoako.Ho latela ntlha e fapaneng ea ho qhibiliha ea tšepe ea brazing, brazing e ka aroloa ka mekhahlelo e 'meli: brazing e bonolo le brazing e thata.

(1) Ho betsa ha bonolo.Brazing e nang le ntlha e qhibilihang e ka tlase ho 450 ° C e bitsoa soft brazing, 'me tšepe e sebelisoang hangata ke brazing lead brazing, e nang le metsi a matle le motlakase oa motlakase mme e sebelisoa haholo lihlahisoa tsa elektroniki, lisebelisoa tsa enjene le likarolo tsa koloi.Matla a lenonyeletso la brazed hangata ke 60 ~ 140MPa.

(2) Ho lla.Brazing e nang le ntlha e qhibilihisang ho feta 450 ° C e bitsoa brazing, 'me lisebelisoa tse tloaelehileng tsa brazing ke lisebelisoa tsa koporo le silevera.Motsoako o nang le tšepe ea tšepe ea tšepe e na le matla a phahameng, conductivity ea motlakase le ho hanyetsa kutu, sebaka se qhibilihang sa tšepe ea filler se tlase, 'me ts'ebetso e ntle, empa theko ea tšepe ea filler e holimo,' me e sebelisoa haholo bakeng sa welding. likarolo tse nang le litlhoko tse phahameng.Brazing e sebelisoa haholo bakeng sa lisebelisoa tsa tšepe le tsa koporo tse nang le matla a maholo, le lisebelisoa tsa brazing.Matla a kopaneng a 200 ~ 490MPa,

Tlhokomeliso: Sebaka sa ho kopana sa lisebelisoa tsa motheo se lokela ho hloeka haholo, kahoo phallo e lokela ho sebelisoa.Karolo ea flux ke ho tlosa litšila tsa oxide le oli holim'a tšepe ea motheo le tšepe ea ho tlatsa, ho sireletsa bokaholimo ba tšepe ea tšepe le tšepe ea motheo ho tsoa ho oxidation, le ho eketsa metsi le capillary fluidity ea filler. tšepe.Sebaka se qhibilihisang sa flux se lokela ho ba se tlaase ho feta sa tšepe ea ho tlatsa, 'me ho bola ha masala a phallo ho tšepe ea motheo le manonyeletso e lokela ho ba tlase.Tsela e tloaelehileng ea brazing flux ke rosin kapa zinc chloride solution, 'me mokhoa o tloaelehileng oa brazing flux ke motsoako oa borax, boric acid le alkaline fluoride.

Ho ea ka mehloli e fapaneng ea mocheso kapa mekhoa ea ho futhumatsa brazing e ka aroloa ka:lelakabe la malakabe, brazing ea induction, brazing ea sebōpi, brazing ea dip, brazing ea ho hanyetsa joalo-joalo.Hobane mocheso o futhumatsang o batla o le tlase nakong ea brazing, o na le tšusumetso e fokolang ts'ebetsong ea lisebelisoa tsa mosebetsi, 'me khatello ea khatello ea weldment le eona e nyenyane.Leha ho le joalo, matla a lenonyeletso la brazed hangata a tlase, 'me ho hanyetsa mocheso ho fokola.

Mokhoa oa ho futhumatsa brazing:Hoo e ka bang mehloli eohle ea ho futhumatsa e ka sebelisoa e le mehloli ea mocheso oa brazing, 'me ho ea ka brazing ena e arotsoe.

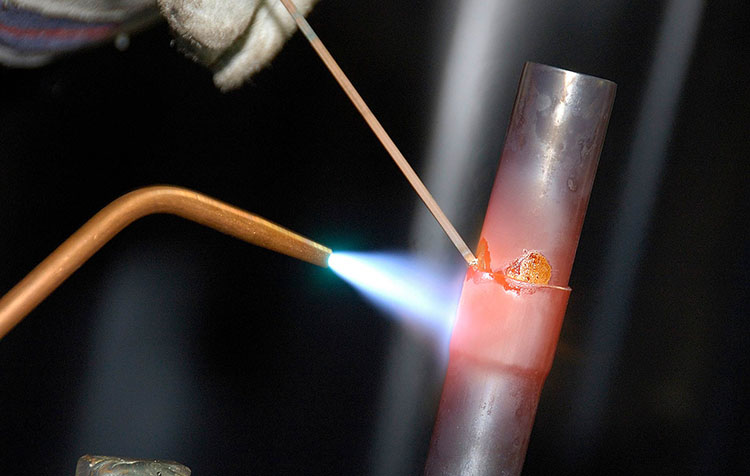

Ho chesa malakabe:ho futhumatsa ka lelakabe la khase, e sebelisoang bakeng sa tšepe ea carbon, tšepe e sa hloekang, carbide, tšepe e entsoeng ka tšepe, li-alloys tsa koporo le tsa koporo, aluminium le aluminium alloy brazing.

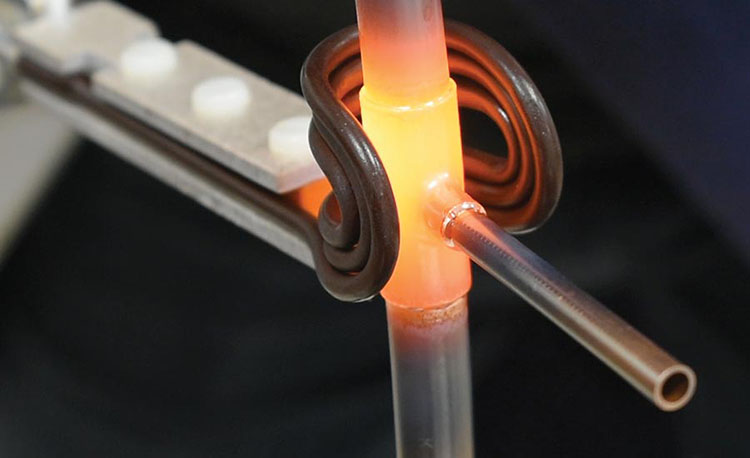

Induction brazing:Tšebeliso ea matla a khoheli a fapanyetsanang ho hlahisa motlakase o kentsoeng karolong ea mocheso oa mocheso o futhumatsang tjheseletsa, bakeng sa sebopeho sa symmetrical sa tjheseletsa, haholo-holo brazing ea phala shaft.

Dip brazing:karolo tjheseletsa karolo e itseng kapa ka ho feletseng qoelisoa ka ho qhibilihisoa letsoai motsoako kapa solder qhibiliha, ho itšetleha ka mocheso oa mecha ea litaba mokelikeli ho finyella tshebetso brazing, e leng tšoauoa ka ho futhumatsa ka potlako, mocheso junifomo, deformation nyenyane ea tjheseletsa karolo.

Ho chesoa ha sebōpi:Li-welds li futhumatsoa ke sebōpi sa ho hanyetsa, se ka sireletsang litšepe ka ho hloekisa kapa ho sebelisa likhase tse fokotsang kapa tse fokolang.

Ntle le moo, ho na le brazing ea tšepe ea solder, brazing ea ho hanyetsa, brazing ea diffusion, brazing ea infrared, brazing ea karabelo, brazing ea electron beam, laser brazing, joalo-joalo.

Brazing e ka sebelisoa ho cheselletsa tšepe ea carbon, tšepe e sa hloekang, superalloy, aluminium, koporo le lisebelisoa tse ling tsa tšepe, hape e ka hokahanya litšepe tse sa tšoaneng, litšepe le tse seng tsa tšepe.E loketse bakeng sa ho tjheseletsa manonyeletso a nang le mojaro o monyenyane kapa ho sebetsa mocheso oa kamore, haholo-holo a loketse bakeng sa ho nepahala, li-welds tse nyenyane le tse rarahaneng tse nang le li-brazed tse ngata.

Nako ea poso: Jul-06-2023