Argon tungsten arc welding e sebelisa argon e le khase e sireletsang ho futhumatsa le ho qhibilihisa thepa ea welding ka boeona (e boetse e qhibiliha ha tšepe ea ho tlatsa e kenngoa) ka arc e hlahisoang pakeng tsa electrode ea tungsten le 'mele oa weld, ebe e etsa welding. ea weld metal Way.Theelectrode ea tungsten,letamo la weld, arc le sebaka se kopaneng sa seam se futhumetseng ke arc se sirelelitsoe ho silafatsoa ke sepakapaka ka phallo ea argon.

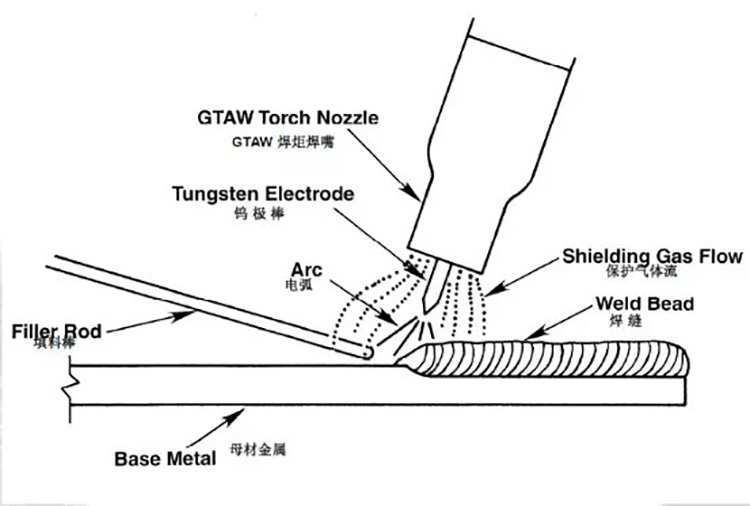

Nakong ea ho cheselletsa argon arc, maemo a amanang le toche, tšepe ea ho tlatsa le ho cheseletsa li tšoana le setšoantšo se ka tlase: bolelele ba arc hangata ke makhetlo a 1 ~ 1.5 bophara ba electrode ea tungsten.Ha welding e emisoa, tšepe ea filler e qala ho ntšoa ka letamong le entsoeng ka ho qhibilihisoa (tšepe ea filler e eketsoa ho ea ka botenya ba weldment), mme pheletso e chesang e ntse e hloka ho lula tlas'a tšireletso ea phallo ea argon ho thibela oxidation ea eona. .

1. Toche ea ho chesoa (toche)

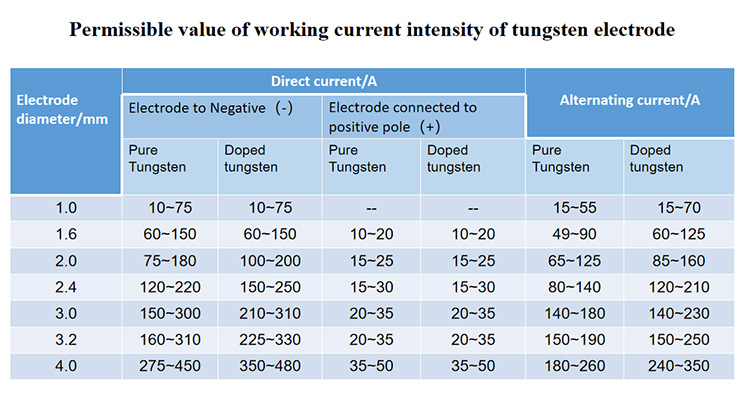

Ntle le ho tiisa electrode ea tungsten le ho fana ka motlakase oa hona joale, toche ea argon tungsten arc welding (eo hape e tsejoang e le toche ea welding) e boetse e hloka ho fafatsa khase e sireletsang.Lithunya tsa li-welding tsa morao-rao li hloka ho sebelisa lithunya tse pholileng ka metsi bakeng sa ho cheselletsa nako e telele.Ka hona, ts'ebeliso e nepahetseng le ts'ireletso ea toche ea welding ke ea bohlokoa haholo.Tungsten electrode load current capacity (A) e bontšoa tafoleng e ka tlase.

2. Tsela ea khase

Tsela ea khase e entsoe ka valve ea ho fokotsa khatello ea argon cylinder, meter ea phallo, hose le valve ea khase ea motlakase (ka hare ho mochine oa welding).Valve e fokotsang khatello e sebelisetsoa ho fokotsa khatello le ho lokisa khatello ea khase e sireletsang.The flowmeter e sebelisetsoa ho lekanya le ho lokisa phallo ea khase e sireletsang.Mechini ea welding ea Argon arc hangata e sebelisa phallo e kopaneng ea decompression flowmeter, e bonolo ebile e ka tšeptjoa ho e sebelisa.

Nakong ea welding ea argon, tlhokahalo ea bohloeki ba khase ea argon ke hore tšepe ea chromium-nickel e lokela ho ba ≥99.7%, 'me tšepe e refractory e lokela ho ba ≥99.98%.

(1) Argon ke khase e sa sebetseng, 'me ha ho bonolo ho itšoara ka lisebelisoa tse ling tsa tšepe le likhase.Ho feta moo, ka lebaka la phello e pholileng ea phallo ea moea, sebaka se amehileng ke mocheso oa weld se nyane mme deformation ea weldment e nyane.Ke khase e sireletsang ka ho fetisisa bakeng sa welding ea argon tungsten arc.

(2) Argon haholo-holo e sebelisoa ho sireletsa ka katleho letamo le entsoeng ka ho qhibilihisoa, ho thibela moea ho senya letamo le qhibilihisitsoeng le ho baka oxidation nakong ea ts'ebetso ea tjheseletsa, 'me ka nako e ts'oanang ka katleho ho arola moea sebakeng sa weld, e le hore sebaka sa weld se be teng. sireletsoa le tshebetso tjheseletsa e ntlafatsoa.

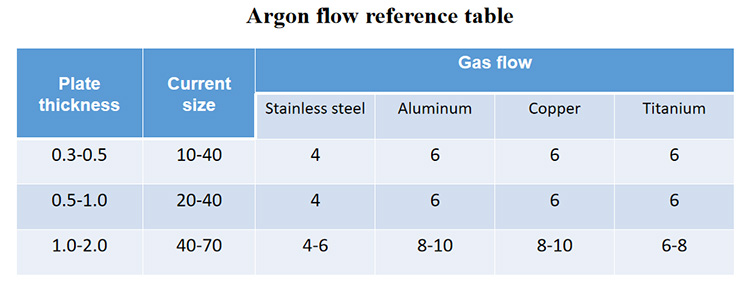

(3) Mokhoa oa ho lokisa o khethoa ho ea ka thepa ea tšepe e lokelang ho chesetsoa, boholo ba hona joale, le mokhoa oa ho cheselletsa: ho feta hona joale, ho na le khase e sireletsang haholoanyane.Bakeng sa lisebelisoa tse sebetsang, khase e sireletsang e lokela ho matlafatsoa ho eketsa sekhahla sa phallo.

3. Litekanyetso tsa lintlha

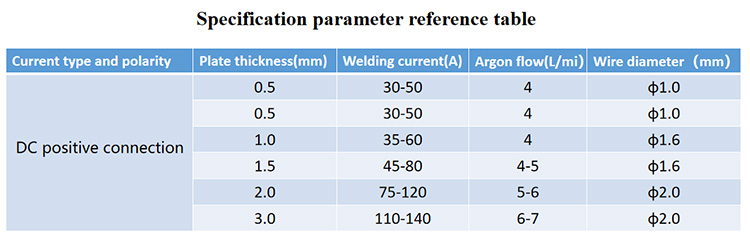

Mekhahlelo e tloaelehileng ea argon tungsten arc welding haholo-holo e kenyelletsa hona joale, voltage, lebelo la ho tjheseletsa, le phallo ea khase ea argon, 'me boleng ba bona bo amana le mofuta oa thepa e lokelang ho chesoa, botenya ba poleiti le mofuta o kopaneng.

Mekhahlelo e setseng e joalo ka bolelele ba eleketrode ea tungsten e hlahelletseng ho tsoa molomong hangata ke makhetlo a 1-2 bophara ba eleketrode ea tungsten, sebaka se pakeng tsa eleketrode ea tungsten le weldment (bolelele ba arc) hangata ke makhetlo a 1.5 bophara ba tungsten. electrode, 'me boholo ba nozzle bo khethoa ka mor'a hore boleng ba hona joale ba tjheseletsa bo khethoe.Khetha hape.

Litlhaloso tse akaretsang tsa tšepe ea tšepe ea argon arc welding ke tse latelang:

4. Ho hloekisa pele ho tjheseletsa

Tungsten argon arc welding e na le kutloelo-bohloko haholo ho tšilafalo ea weldment le filler tšepe bokaholimo, kahoo mafura, barbotage, lubricant le oxide filimi holim'a tjheseletsa lokela ho tlosoa pele tjheseletsa.

5. Theknoloji ea polokeho

Basebelisi ba argon tungsten arc welding ba tlameha ho roala limaske tsa hlooho, liatlana, liaparo tsa mosebetsi le lieta tsa mosebetsi ho qoba ho chesoa ke mahlaseli a kotsi le a infrared arc.Mechini ea welding ea Steyr tungsten argon arc e na le lisebelisoa tse qalang tsa maqhubu a holimo.Le hoja motlakase o nang le matla a tlaase a matla a phahameng a matla a phahameng a motlakase a ke ke a tšosa mokhanni, ha ts'ebetso ea ho kenya letsoho e fokola, motlakase o phahameng o tla chesa letlalo la letsoho la opereishene, 'me ho thata ho phekola, kahoo ts'ebetso ea ho kenya letsoho e tla chesa. ea tjheseletsa handle lokela ho hlahlojoa khafetsa.Nakong ea welding ea argon tungsten arc, moea o kenang sebakeng sa welding o lokela ho ntlafatsoa.

Hlokomela: Ntho ea bohlokoa ke ho ba le tsebo le dexterous.Botenya ba boto, nako ea ho tobetsa, le hona joale kaofela li amana, 'me li hloka ho sebelisana hammoho.

Ha u cheseletsa, u se ke ua supa ntlha ea nale moo ho chesetsoang teng qalong, 'me ue otla e se na letho pele ho ntša moea ka phala, e le hore tjheseletsa e se ke ea phatloha 'me ho ke ke ha e-ba le matheba a matšo.Metsotsoana e seng mekae, ka tsela ena, tšepe e sa hloekang e sirelelitsoe ke khase ea argon nakong ea ho pholile, kahoo e ke ke ea e-ba e ntšo, esita le metsi a ho hlatsoa le letlapa la polishing li bolokiloe.Sena se ka sebelisoa feela bakeng sa ho cheselletsa letheba.Haeba u hula tjheseletsa sebaka se selelele, ha ho na tsela.Ka sebele boto e tla fetola 'mala.U tlameha ho emela ho belisoa le ho hloekisoa.

Nako ea poso: May-16-2023