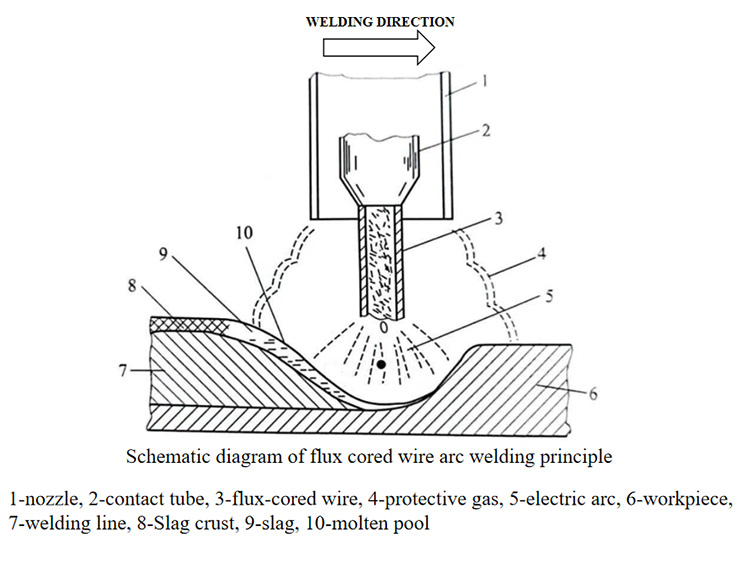

Ke engflux-cored arc welding?

Flux-cored wire arc welding ke mokhoa oa ho tjheseletsa o sebelisang arc pakeng tsa terata e nang le flux-cored le workpiece ho futhumatsa, 'me lebitso la eona la Senyesemane ke FCAW feela.Tlas'a ketso ea mocheso oa arc, tšepe ea tšepe ea welding le workpiece e kopantsoe ka ho qhibiliha, ho etsa letamo la weld, arc pele ka mor'a crystallization ea mohatla oa letamo la weld.

Flux-cored terata ke eng?Litšobotsi tsa cartridge ke life?

Flux-cored welding terata ke mofuta oa terata ea tjheseletsa e entsoeng ka ho pitikisa tšepe e tšesaane ho phala ea tšepe kapa phala ea tšepe e nang le sebopeho se ikhethileng, e tlatsang phala ka likarolo tse itseng tsa phofo, le ho taka.Motsoako oa motsoako oa phofo o tšoana le oa ho roala ha electrode, e leng haholo-holo e entsoeng ka arc stabilizing agent, slag forming agent, gas forming agent, alloying agent, deoxidizing agent, joalo-joalo.

Karolo ea phallo ea terata ea flux-cored ke efe?

Karolo ea phallo e tšoana le ea ho roala electrode, 'me ho na le haholo-holo mefuta e latelang.

① Tšireletso ea likarolo tse ling tsa ho bola ha welding flux, tse ling lia qhibiliha!Ho bola ha welding flux ho ntša khase, e fanang ka tšireletso e itseng kapa e mengata.Mokelikeli o qhibilihisitsoeng o etsa lesela le qhibilihisitsoeng, le koahelang bokaholimo ba lerotholi le letamo le qhibilihisitsoeng, 'me tšepe ea metsi e e sireletsa.

② Arc stabilizer ka har'a cartridge ea arc stabilizer e ka tsitsisa arc le ho fokotsa sekhahla sa spatter.

③ Ts'ebetso ea ho kopanya Likarolo tse ling tsa alloy tse bohareng li ka kopanya weld.

④ Lisebelisoa tsa alloy deoxidation tsa slag li ka sebetsana le litšepe tse metsi.Ntlafatsa sebopeho sa tšepe ea weld, ntlafatsa thepa ea eona ea mochini.

Ho phaella moo, slag e koahetsoeng e ka boela ea fokotsa lebelo la ho pholile ha letamo le qhibilihisitsoeng, le lelefatsa nako ea ho ba teng ha letamo le qhibilihisitsoeng, le leng molemo ho fokotsa litaba tsa khase e kotsi ka har'a weld le ho thibela porosity.

Ho na le mefuta ea mofuta ofe ea flux cored arc welding?

Ho na le mefuta e 'meli ea flux cored wire arc welding (FCAW-G) le self-protection welding (FCAW-S), ho itšetlehile ka hore na khase e sireletsang ka ntle e sebelisoa kapa che.

Mohala o sirelelitsoeng ka khase oa terata e nang le flux-cores hangata o sebelisa carbon dioxide kapa carbon dioxide hammoho le argon e le khase e sireletsang, 'me phallo ea terata e na le ntho e nyenyane ea khase.Mokhoa ona o ts'oana le ts'ebeliso e akaretsang ea khase e sirelelitsoeng.Ho tjheseletsa ho itšireletsa ha ho hloke khase e sireletsang ka ntle.Ho na le palo e kholo ea khase ho phallo, 'me khase le slag e bolileng ke khase li sebelisetsoa tšireletso.

Melemo ea Flux-cored arc welding ke efe?

Flux-cored arc welding e na le melemo e latelang.

(1) Tlhahiso e phahameng ea welding e phahameng ea ho qhibiliha (ho fihla ho 85% ~ 90%), lebelo la ho qhibiliha ka potlako;Bakeng sa tjheseletsa e bataletseng, lebelo la ho roala ke makhetlo a 1.5 ho feta a tjheseletsa ea li-arc, 'me bakeng sa maemo a mang a tjheseletsa, ke makhetlo a 3-5 a ho cheseletsa arc ka letsoho.

② Splash e nyane, weld e theha setsi se setle sa lithethefatsi se ekelitse arc stabilizer, ka hona, botsitso ba arc, splash e nyane, sebopeho se setle sa weld.Kaha letamo le entsoeng ka ho qhibilihisoa le koahetsoe ke slag e entsoeng ka ho qhibilihisoa, sebopeho sa weld surface se molemo haholo ho feta sa carbon dioxide welding.

(3) Boleng bo phahameng ba welding Ka lebaka la tšireletso e kopantsoeng ea khase ea slag, e ka thibela ka katleho khase e kotsi ho kena sebakeng sa welding.Ho phaella moo, nako ea ho ba teng ha letamo le qhibilihisitsoeng ke nako e telele, e leng se loketseng ho na ha khase, kahoo weld e na le lintho tse fokolang tsa haedrojene le ho hanyetsa porosity e ntle.

(4) Ho ikamahanya le maemo ho matla ho hloka feela ho lokisa sebopeho sa terata ea solder, e ka fihlela litlhoko tsa litšepe tse fapaneng ka sebopeho sa weld.

Ke mefokolo efe ea ho cheselletsa arc ea flux-cored?

Mefokolo ea flux-cored arc welding ke tse latelang.

Ha ho bapisoa le welding e sirelelitsoeng ka khase, theko ea terata ea welding e holimo 'me mokhoa oa ho etsa thepa o rarahane.

② Ho fepa ka terata ho thata, hoa hlokahala ho sebelisa mochini oa ho fepa ka terata oo khatello ea hae ea clamping e ka lokisoang ka nepo.

③ Cartridge e bonolo ho monya mongobo, kahoo hoa hlokahala ho boloka terata ea welding ka tieo.

④ Ho tlosoa ha slag hoa hlokahala ka mor'a ho cheselletsa.

⑤ Mosi o mongata le likhase tse kotsi li hlahisoa ts'ebetsong ea welding, kahoo moea o lokela ho matlafatsoa.

Ke khase efe e sireletsang e atisang ho sebelisoa ho cheselletsa arc-cored arc?Litšobotsi tsa e mong le e mong ke life?

Flux cored wire arc welding hangata e sebelisa khase e hloekileng ea carbon dioxide kapa carbon dioxide le khase ea argon e le khase e sireletsang.Mofuta oa khase o hloka ho khethoa ho ea ka terata ea flux-cored e sebelisitsoeng.

Argon e na le ionized habonolo, kahoo ho bonolo ho finyella phetoho ea ejection ho argon arc.Ha karolo ea argon ea motsoako oa khase e se ka tlase ho 75%, ho chesoa ha terata ea flux cored arc ho ka fihlela phetoho e tsitsitseng ea jete.Ka ho fokotseha ha litaba tsa argon, botebo ba ho kenella boa eketseha, empa botsitso ba arc bo fokotseha 'me sekhahla sa spatter se eketseha.Ka hona, motsoako o nepahetseng oa khase ke 75%Ar + 25% CO2.Ho feta moo, Ar + 2% O2 e ka boela ea sebelisoa bakeng sa motsoako oa khase.

Ha khase e hloekileng ea CO2 e khethoa, e tla bola tlas'a ketso ea mocheso oa arc 'me e hlahise palo e kholo ea liathomo tsa oksijene, tse tla oxidize manganese, silicon le likarolo tse ling ka letamong le entsoeng ka ho qhibilihisoa, e leng se lebisang ho chesoeng ha likarolo tsa motsoako.Ka hona, ho lokela ho sebelisoa terata e nang le manganese e phahameng le silicon.

Nako ea poso: May-09-2023