Selelekela

Kaha 'mele oa koloi ke oona o tsamaisang likarolo tse ling tsa koloi, theknoloji ea eona ea ho etsa thepa e khetholla ka ho toba boleng ba kakaretso ba koloi.Welding ke ts'ebetso ea bohlokoa ea tlhahiso ts'ebetsong ea tlhahiso ea 'mele oa likoloi.Hajoale, mahlale a tjheseletsa a sebelisoang bakeng sa ho cheselletsa 'mele oa likoloi haholo-holo a kenyelletsa welding spot welding, MIG welding, MAG welding le laser welding.

Theknoloji ea ho tjheseletsa ka laser e le theknoloji e tsoetseng pele ea ho kopanya tjheseletsa ea optoelectromechanical, ha e bapisoa le theknoloji ea khale ea ho tjheseletsa 'mele ea likoloi, e na le melemo ea ho ba le matla a mangata a matla, lebelo la ho tjheseletsa ka potlako, khatello e nyenyane ea welding le deformation, le ho fetoha habonolo.

Sebopeho sa 'mele oa koloi se rarahane, 'me likarolo tsa eona li na le marako a masesaane ebile a kobehile.Ho cheselletsa 'mele oa koloi ho tobane le mathata a mang, joalo ka ho fetoha ha thepa ea' mele, botenya bo fapaneng ba likarolo tsa 'mele, litsela tse fapaneng tsa ho cheselletsa le mefuta e kopaneng.Ntle le moo, ho cheselletsa 'mele oa koloi ho na le litlhoko tse phahameng mabapi le boleng ba welding le katleho ea welding.

Ho ipapisitsoe le litekanyetso tse nepahetseng tsa ts'ebetso ea welding, laser welding e ka netefatsa matla a mokhathala a phahameng le ho tiea ha likarolo tsa bohlokoa tsa 'mele oa koloi, e le ho netefatsa boleng ba tjheseletsa le bophelo ba ts'ebeletso ea' mele oa koloi.Theknoloji ea welding ea laser e ka ikamahanya le mefuta e fapaneng ea manonyeletso, botenya bo fapaneng le mefuta e fapaneng ea lisebelisoa tsa likarolo tsa 'mele oa koloi, ho fihlela litlhoko tse feto-fetohang tsa tlhahiso ea' mele ea likoloi.Ka hona, theknoloji ea welding ea laser ke mokhoa oa bohlokoa oa tekheniki oa ho fihlela nts'etsopele ea boleng bo holimo ea indasteri ea likoloi.

Theknoloji ea welding ea laser ea 'mele oa koloi

Theknoloji ea ho kenella ka har'a laser e tebileng ea 'mele oa koloi

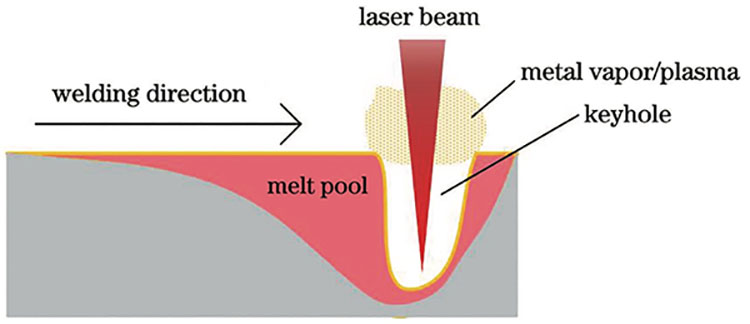

Molao-motheo oa ts'ebetso ea ho kenella ka har'a laser e tebileng (setšoantšo sa 1) ke ka tsela e latelang: ha matla a matla a laser a fihla boemong bo itseng, holim'a lintho tse bonahalang eka ke mouoane, ho etsa senotlolo.Ha khatello ea tšepe ea mouoane ka mokoting e fihla ho leka-lekana e matla le khatello e tsitsitseng le tsitsipano ea holim'a metsi a potolohileng, laser e ka khasetsoa ho ea tlase ho lesoba ka lesoba la senotlolo, 'me ka ho tsamaea ha lebone la laser, ho tsoela pele. weld e thehoa.Nakong ea ts'ebetso ea welding e tebileng ea laser, ha ho na tlhoko ea ho eketsa flux kapa filler, 'me lisebelisoa tsa workpiece ka boeona li ka kopanngoa hammoho.

FEIE.1 Sets'oants'o sa moralo oa ts'ebetso ea welding e tebileng ea laser

Weld e fumanoang ka laser deep penetration welding ka kakaretso e boreleli ebile e otlolohile, 'me deformation e nyane, e thusang ho ntlafatsa ho nepahala ha tlhahiso ea' mele oa koloi.Matla a phahameng a matla a weld a netefatsa boleng ba ho cheselletsa 'mele oa koloi.Lebelo la welding le potlakile, e leng se loketseng ho ntlafatsa katleho ea tlhahiso ea welding.

Ts'ebetsong ea ho tjheseletsa 'mele oa koloi, ts'ebeliso ea ts'ebetso ea welding ea laser e tebileng e ka fokotsa haholo palo ea likarolo, liforomo le lisebelisoa tsa tjheseletsa, ka hona ho fokotsa boima ba' mele le litšenyehelo tsa tlhahiso.Leha ho le joalo, ts'ebetso ea welding ea laser e tebileng e na le mamello e fokolang bakeng sa lekhalo la kopano ea likarolo tse cheselitsoeng, 'me lekhalo la kopano le hloka ho laoloa pakeng tsa 0.05 le 2 mm.Haeba lekhalo la kopano le le leholo haholo, ho tla ba le mefokolo ea welding joalo ka li-pores.

Lipatlisiso tsa morao-rao li bontša hore tjheseletsa e nang le sebopeho se setle sa holim'a metsi, bokooa bo fokolang ba ka hare le thepa e babatsehang ea mechine e ka fumanoa ka ho ntlafatsa mekhoa ea ts'ebetso ea laser e tebileng ea ho kenella ka hare ho tjheseletsa ea thepa e tšoanang ea 'mele oa koloi.Mehato e metle ea mochini oa weld e ka fihlela litlhoko tsa likarolo tsa welding tsa 'mele oa koloi.Leha ho le joalo, ho tjheseletsa 'mele oa koloi, theknoloji e fapaneng ea laser e tebileng ea ho kenella ka hare e emeloang ke alloy ea aluminium le tšepe ha e so holile.Le hoja li-welding seams tse nang le ts'ebetso e ntle haholo li ka fumanoa ka ho kenyelletsa likarolo tsa phetoho, mochine oa tšusumetso ea lisebelisoa tse fapaneng tsa phetoho holim'a IMC le mochine oa bona oa ts'ebetso ho weld microstructure ha o hlake, 'me lipatlisiso tse ling lia hlokahala.

Automobile body laser wire filling process

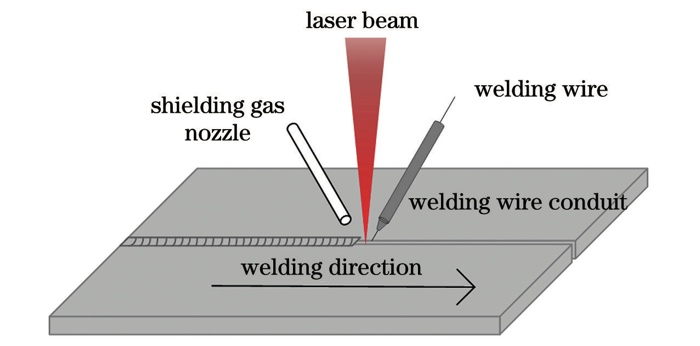

Molao-motheo oa ts'ebetso ea ho tjheseletsa terata ea laser ke e latelang: lenonyeletso le cheselitsoeng le thehoa ka ho tlatsa terata e itseng ea welding ka har'a weld kapa ho fepa terata ea welding ka nako e le 'ngoe nakong ea ts'ebetso ea laser welding.Sena se lekana le ho kenya lisebelisoa tsa terata tse ka bang homogeneous ka har'a letamo la weld nakong ea welding e tebileng ea laser.Sets'oants'o sa moralo oa ts'ebetso ea welding ea laser filler e bonts'itsoe ho Setšoantšo sa 2.

FEIE.2 Setšoantšo sa moralo oa ts'ebetso ea welding ea terata ea laser

Ha ho bapisoa le welding ea laser deep penetration welding, laser wire filling welding e na le melemo e 'meli ho tjheseletsa ea' mele ea koloi: ea pele, e ka ntlafatsa haholo mamello ea lekhalo la kopano pakeng tsa likarolo tsa 'mele oa koloi ho tjheseletsa, le ho rarolla bothata ba hore laser deep penetration welding ho hloka tlhokomelo e ngata haholo;Ea bobeli, kabo ea lithane tsa sebaka sa weld e ka ntlafatsoa ka ho sebelisa lithapo tsa welding tse nang le litaba tse fapaneng tsa sebopeho, ebe ts'ebetso ea weld e ka laoloa.

Ts'ebetsong ea ho etsa 'mele oa likoloi, ts'ebetso ea welding ea laser wire e sebelisoa haholo bakeng sa ho tjheseletsa aluminium alloy le likarolo tsa tšepe tsa' mele.Haholo-holo ts'ebetsong ea welding ea likarolo tsa aluminium alloy ea 'mele oa koloi, tsitsipano e kaholimo ea letamo le qhibilihisitsoeng e nyane, e leng bonolo ho lebisa ho putlama ha letamo le qhibilihisitsoeng, mme ts'ebetso ea ho tlatsa terata ea laser e ka rarolla bothata ba ho putlama ha letamo. ka ho qhibilihisa terata ya ho tjheseletsa.

Theknoloji ea laser brazing ea 'mele oa koloi

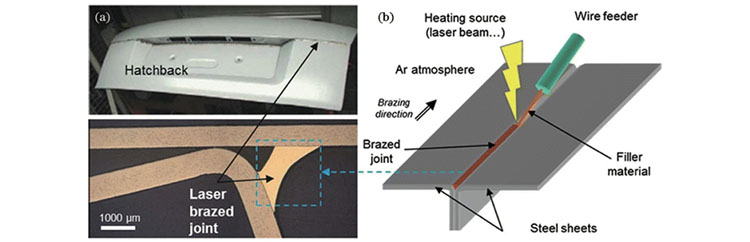

Molao-motheo oa ts'ebetso ea laser brazing ke ka tsela e latelang: laser e sebelisoa e le mohloli oa mocheso, lebone la laser le bonesoa holim'a terata ea welding ka mor'a hore e tsepamise maikutlo, terata ea welding ea qhibiliha, terata e qhibilihisitsoeng e theoha ebe e tlatsoa pakeng tsa likarolo ho tjheseletsa, le liphello metallurgical tse kang ho qhibiliha le diffusion etsahala pakeng tsa tšepe filler le workpiece, e le hore workpiece e amana.Ho fapana le ts'ebetso ea welding ea terata ea laser, ts'ebetso ea laser brazing e qhibilihisa terata feela mme ha e qhibilihe sesebedisoa sa mosebetsi hore se tsoe.Laser brazing e na le botsitso bo botle ba welding, empa matla a tsitsipano a weld a tlase.FEIE.3 e bonts'a ts'ebeliso ea ts'ebetso ea laser brazing ho welding ea sekoaelo sa koloi.

FEIE.3 Ho sebelisoa ha laser brazing koloing: (a) laser welding ea hood e ka morao;(b) Setšoantšo sa schematic sa laser brazing

Ts'ebetsong ea ho tjheseletsa 'mele oa koloi, mokhoa oa laser brazing ke haholo-holo ho tjheseletsa likarolo tsa' mele tse nang le litlhoko tse tlase tsa matla a manonyeletso, joalo ka ho cheselletsa lipakeng tsa sekoaelo se kaholimo le lebota le lehlakoreng la 'mele, ho cheselletsa lipakeng tsa karolo e kaholimo le e tlase ea kutu. sekoahelo, joalo-joalo, Volkswagen, Audi le tse ling tse phahameng-qetellong mehlala ea sekoahelo ka holimo ba sebelisa laser brazing tshebetso.

Litšitiso tse ka sehloohong tsa laser brazing welding seam ea 'mele oa koloi li kenyelletsa ho loma ka bohale, porosity, weld deformation, joalo-joalo. Litšitiso li ka hatelloa ka ho hlaka ka ho fetola mekhoa ea ts'ebetso le ho sebelisa mekhoa e mengata ea laser brazing.

Laser arc composite welding theknoloji ea 'mele oa koloi

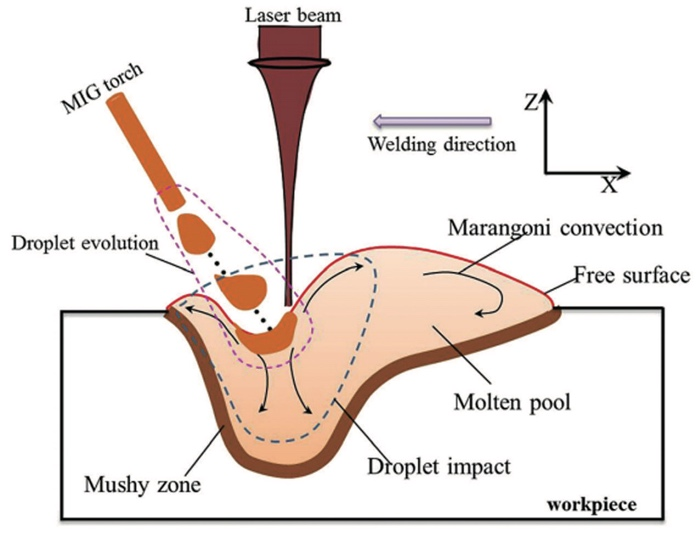

Molao-motheo oa laser-arc composite tjheseletsa thulaganyou e ke ka tsela e latelang: ho sebelisa mehloli e 'meli mocheso oa laser le arc ho nka khato holim'a workpiece ho tjheseletsa ka nako e tšoanang, workpiece e qhibiliha le ho tiisa ho theha weld.Setšoantšo sa 4 se bonts'a sets'oants'o sa moralo oa ts'ebetso ea welding ea laser-arc composite.

FEIE.4 Sets'oants'o sa moralo oa ts'ebetso ea welding ea laser-arc composite

Laser-arc composite welding e na le melemo ea bobeli laser welding le arc welding: pele, tlasa ts'ebetso ea mehloli e habeli ea mocheso, lebelo la welding le ntlafatsoa, tlhahiso ea mocheso e nyane, deformation ea weld e nyane, le litšobotsi tsa welding ea laser. lia hlokomeloa;Ea bobeli, e na le bokhoni bo betere ba ho koala le ho mamella lekhalo la kopano;Ntlha ea boraro, sekhahla sa ho tiea ha letamo le entsoeng ka ho qhibilihisoa se tsamaea butle, e leng se loketseng ho felisa mefokolo ea litšepe tse kang li-pores le mapetsong, le ho ntlafatsa sebopeho le tšebetso ea sebaka se amehileng ke mocheso.Ea bone, ka lebaka la phello ea arc, e ka cheselletsa lisebelisoa tse nang le reflectivity e phahameng le conductivity e phahameng ea mocheso, 'me mefuta e mengata ea lisebelisoa tsa kopo e pharaletse.

Ts'ebetsong ea ho etsa 'mele oa likoloi, mokhoa oa ho tjheseletsa oa laser-arc composite haholo-holo ke ho cheselletsa likarolo tsa aluminium tsa' mele le litšepe tse sa tšoaneng tsa aluminium-tšepe, 'me welding e etsoa bakeng sa likarolo tse nang le likheo tse kholo tsa kopano, joalo ka ho tjheseletsa ha likarolo tse ling. monyako oa koloi, hobane lekhalo la kopano le loketse papali ea borokho ba laser-arc composite welding.Ntle le moo, theknoloji ea welding ea laser-MIG arc composite e boetse e sebelisoa sebakeng se kaholimo sa lehlakore sa 'mele oa Audi.

Ts'ebetsong ea ho tjheseletsa 'mele oa koloi, welding ea laser-arc composite e na le monyetla oa ho mamella lekhalo le leholo ho feta welding ea laser e le' ngoe, empa boemo bo lekanyelitsoeng ba laser le arc, liparamente tsa welding tsa laser, liparamente tsa arc le lintlha tse ling li lokela ho nahanoa ka botlalo.Boitšoaro ba mocheso le boima ba phetisetso ea laser-arc welding e rarahane, haholo-holo mochini oa taolo ea matla le botenya ba IMC le taolo ea sebopeho ho tjheseletsa ea thepa e sa tšoaneng e ntse e sa hlaka, 'me lipatlisiso tse ling lia hlokahala.

Mekhoa e meng ea li-welding laser ea 'mele ea likoloi

Laser e tebileng ea ho kenella ka tjheseletso, tjheseletsa ea terata ea laser, brazing ea laser le laser-arc composite welding le lits'ebetso tse ling tsa welding e bile khopolo e tsoetseng pele le lits'ebetso tse ngata tse sebetsang.Ka ntlafatso ea litlhoko tsa indasteri ea likoloi bakeng sa ts'ebetso ea ho cheselletsa 'mele le keketseho ea tlhokahalo ea lisebelisoa tse fapaneng tsa ho tjheseletsa ha thepa ea likoloi tse bobebe, laser spot welding, laser swing welding, multi-laser beam welding le laser flight welding li se li lebisitsoe tlhokomelo. ho.

Mokhoa oa ho tjheseletsa letheba la laser

Laser spot welding ke theknoloji e tsoetseng pele ea welding ea laser, e nang le melemo ea ho potlakisa lebelo le ho nepahala ho phahameng.Molao-motheo oa ho tjheseletsa letheba la laser ke ho tsepamisa seketsoana sa laser ho isa ntlheng e itseng karolong e lokelang ho ts'oaroa, e le hore tšepe e sebakeng seo e qhibilihe hang-hang, ka ho lokisa sekhahla sa laser ho fihlela welding ea mocheso oa mocheso kapa phello e tebileng ea fusion. , ha lebone la laser le emisa ho sebetsa, tšepe ea mokelikeli e phalla hape, e tiileng ho theha lenonyeletso.

Ho na le mefuta e 'meli ea mantlha ea tjheseletsa letheba la laser: welding ea pulsed laser spot le welding e tsoelang pele ea laser spot.Pulsed laser spot welding laser beam peak energy e phahame, empa nako ea ts'ebetso e khuts'oane, hangata e sebelisoa bakeng sa motsoako oa magnesium, motsoako oa aluminium le litšepe tse ling tse bobebe.Ka karolelano matla a laser beam ho continuous laser spot welding a phahame, nako ea ketso ea laser e telele, 'me e sebelisoa haholo ho cheselletsa tšepe.

Mabapi le ho tjheseletsa 'mele oa koloi, ha ho bapisoa le ho tjheseletsa letheba, laser letheba tjheseletsa e na le melemo ea ho se kopane, letheba tjheseletsa trajectory ka etselitsoe ho ikemela, joalo-joalo, e ka kopana le ditlhoko tsa boleng bo phahameng tjheseletsa tlas'a likheo tse fapaneng lap lap. thepa ea 'mele oa koloi.

Laser swing tjheseletsa tshebetso

Laser swing welding ke theknoloji e ncha ea welding ea laser e hlahisitsoeng lilemong tsa morao tjena, e 'nileng ea ameha haholo.Molao-motheo oa theknoloji ena ke: ka ho kopanya sehlopha sa galvanometer holim'a hlooho ea laser welding, lebone la laser le potlakile, le hlophisehile ebile le le boemong bo fokolang, e le ho finyella phello ea lebone la laser le tsoelang pele ha le ntse le susumetsa.

Litsela tse ka sehloohong tsa ho sisinyeha ha laser swing welding li kenyelletsa ho tsubella ho pota-pota, ho tsubella ha longitudinal, ho tsokotsa ho chitja le ho sesa ho sa feleng.Ts'ebetso ea welding ea laser swing e na le melemo e mengata ho tjheseletsa 'mele oa koloi.Tlas'a ketso ea lebone la laser, boemo ba phallo ea letamo le qhibilihisitsoeng bo fetoha haholo.Ka hona, ts'ebetso e ke ke ea felisa feela sekoli se sa tsitsang, ho fihlela ntlafatso ea lijo-thollo le ho hatella porosity ho cheselleng thepa e tšoanang ea 'mele oa koloi.Ntle le moo, e ka boela ea ntlafatsa mathata a kang ho tsoakana ho sa lekaneng ha lisebelisoa tse fapaneng le thepa e mpe ea mochini oa li-welds ho cheselletsa thepa e fapaneng ea 'mele oa koloi.

Multi-laser beam welding process

Hajoale, laser fiber optical e ka aroloa ka libalaka tse ngata tsa laser ka module ea splitter e kentsoeng hloohong ea welding.Multi-laser beam welding e lekana le ho sebelisa mehloli e mengata ea mocheso ts'ebetsong ea ho tjheseletsa, ka ho fetola kabo ea matla a sefate, maballo a fapaneng a ka finyella mesebetsi e fapaneng, e kang: lebone le nang le matla a phahameng a matla ke sefate se seholo, se ikarabellang bakeng sa ho teba. ho kenya tjheseletsa;Matla a tlase a matla a sefate a ka hloekisa le ho futhumatsa bokaholimo ba thepa, 'me a eketsa ho monya matla a beam ea laser ka thepa.

Lintho tse entsoeng ka tšepe tse matla a phahameng a Galvanized li sebelisoa haholo 'meleng oa koloi.Theknoloji ea li-welding ea multilaser e ka ntlafatsa boits'oaro ba mouoane oa zinki le boits'oaro bo matla ba letamo le qhibilihisitsoeng ts'ebetsong ea ho tjheseletsa ka poleiti ea tšepe e entsoeng ka masenke, ho ntlafatsa bothata ba ho fafatsa, le ho matlafatsa matla a ts'ebetso ea weld.

Mokhoa oa ho tjheseletsa sefofane ka laser

Theknoloji ea ho tjheseletsa sefofane ka laser ke theknoloji e ncha ea laser welding, e nang le ts'ebetso e phahameng ea ho cheselletsa 'me e ka etsoa ka boikemelo.Molao-motheo oa motheo oa laser flight welding ke hore ha lebone la laser le etsahala ho liipone tsa X le Y tsa seipone sa ho hlahloba, Angle ea seipone e laoloa ke mananeo a ikemetseng ho finyella ho kheloha ha lebone la laser ho Angle leha e le efe.

Mokhoa oa setso oa laser oa 'mele oa koloi o itšetlehile haholo ka motsamao oa synchronous oa hlooho ea welding ea laser e khannoang ke roboto ea welding ho fihlela phello ea welding.Leha ho le joalo, bokhoni ba ho cheselletsa 'mele oa koloi bo fokotsehile haholo ke ts'ebetso e pheta-phetoang ea liroboto tsa welding ka lebaka la palo e kholo ea li-welds le bolelele bo bolelele ba li-welds.Ka lehlakoreng le leng, laser flight welding e hloka feela ho fetola Angle ea seipone ho finyella welding ka har'a mefuta e itseng.Ka hona, theknoloji ea welding ea sefofane sa laser e ka ntlafatsa haholo ts'ebetso ea tjheseletsa mme e na le tebello e pharaletseng ea ts'ebeliso.

Kakaretso le tebello

Ka nts'etsopele ea indasteri ea likoloi, theknoloji ea nakong e tlang ea ho tjheseletsa 'mele e tla tsoela pele ho hola ka likarolo tse peli: ts'ebetso ea welding le theknoloji e bohlale.

'Mele oa koloi, haholo-holo 'mele o mocha oa koloi, o ntse o tsoela pele ka tsela e bobebe.Li-alloys tse bobebe, lisebelisoa tse kopaneng le lisebelisoa tse fapaneng li tla sebelisoa haholo 'meleng oa koloi, ts'ebetso e tloaelehileng ea welding ea laser e thata ho fihlela litlhoko tsa eona tsa welding, kahoo ts'ebetso ea welding ea boleng bo holimo le e sebetsang e tla fetoha mokhoa oa nts'etsopele ea nakong e tlang.

Lilemong tsa morao tjena, lits'ebetso tse ntseng li hlaha tsa welding ea laser, joalo ka laser swing welding, multi-laser beam welding, laser flight welding, joalo-joalo, esale e le lipatlisiso tsa theory le tlhahlobo ea ts'ebetso ho latela boleng ba welding le ts'ebetso ea welding.Nakong e tlang, hoa hlokahala ho kopanya haufi-ufi ts'ebetso ea welding ea laser e hlahang le lisebelisoa tse bobebe le lisebelisoa tse sa tšoaneng tsa li-welding tsa 'mele oa koloi, ho etsa lipatlisiso tse tebileng mabapi le moralo oa laser beam swing trajectory, mochine oa ts'ebetso oa matla a mangata a laser. le ho ntlafatsa ts'ebetso ea ho tjheseletsa ha sefofane, le ho hlahloba ts'ebetso ea ho cheseletsa 'mele ea koloi e butsoitseng.

Theknoloji ea laser welding ea 'mele oa koloi e kopantsoe ka botebo le theknoloji e bohlale.Pono ea nako ea 'nete ea boemo ba "laser welding" ea' mele oa koloi le taolo ea maikutlo ea liparamente tsa ts'ebetso li bapala karolo ea bohlokoa ho boleng ba welding.Theknoloji ea morao-rao e bohlale ea welding ea laser e sebelisoa haholo bakeng sa moralo oa pele oa welding trajectory le ho latedisa le ho hlahloba boleng ba kamora ho tjheseletsa.Lapeng le kantle ho naha, lipatlisiso tse mabapi le ho bona sekoli sa welding le taolo e feto-fetohang ea parametha e ntse e le mohatong oa pele, 'me theknoloji ea taolo e feto-fetohang ea laser ha e so sebelisoe indastering ea likoloi.

Ka hona, ka lebaka la litšoaneleho tsa ts'ebeliso ea theknoloji ea welding ea laser nakong ea ho cheselletsa 'mele oa koloi, sistimi e bohlale ea ho tjheseletsa laser e nang le li-sensor tse ngata tse tsoetseng pele joalo ka mantlha le sistimi ea taolo ea liroboto tse lebelo le holimo le tse nepahetseng. e ntlafalitsoeng nakong e tlang ho netefatsa nako ea nnete le ho nepahala ha likarolo tsohle tsa theknoloji e bohlale ea welding laser.Bula sehokelo sa "pre-welding trajectory planning - parameter adaptive control of welding quality online access after welding" ho etsa bonnete ba hore ts'ebetso ea boleng bo holimo le e sebetsang hantle.

Nako ea poso: Oct-16-2023