-

The barbotage phetha karolo e rarahaneng metallurgical karabelo le liphetoho 'meleng le lik'hemik'hale tshebetso tjheseletsa, eo ha e le hantle hlōla mathata a tjheseletsa photo photo photo photo eleketrode, kahoo barbotage ke e' ngoe ea lintlha tse ka sehloohong ho fumana hore na boleng ba tšepe weld.Ho roala ka elektrode:...Bala haholoanyane»

-

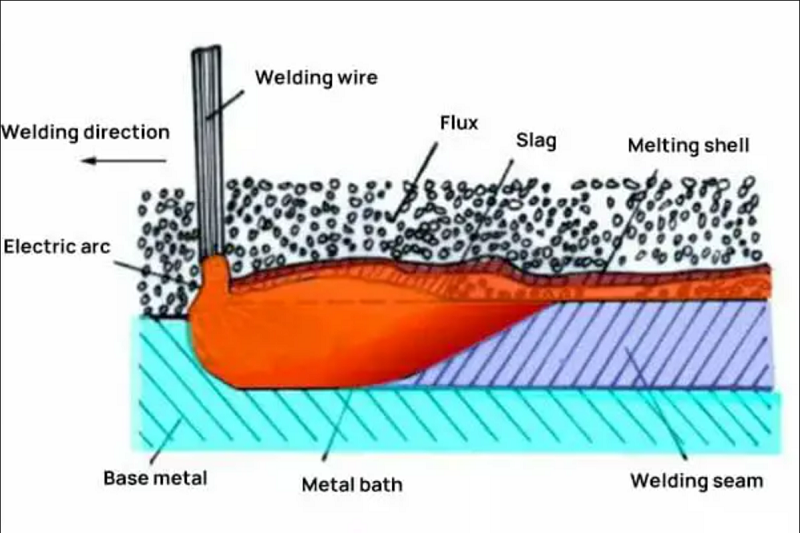

FLUX- Flux ke sesebelisoa sa ho cheselletsa granular.Nakong ea welding, e ka qhibiliha ho etsa slag le khase, e phethang karolo e sireletsang le ea metallurgic holim'a letamo le qhibilihisitsoeng.Constituent Flux e entsoe ka 'mabole, quartz, fluorite le ores tse ling le titanium dioxide, selulose le tse ling ...Bala haholoanyane»

-

Welding ke ts'ebetso eo ho eona lisebelisoa tsa li-workpieces tse lokelang ho chesetsoa (tse tšoanang kapa tse fapaneng) li kopantsoe ka ho futhumatsa kapa khatello kapa ka bobeli, le ka kapa ntle le lisebelisoa tsa ho tlatsa, e le hore lisebelisoa tsa li-workpieces li hokahane lipakeng tsa liathomo ho theha. kgokelo.Joale lintlha tsa bohlokoa ke life...Bala haholoanyane»

-

TIG 1. Kopo : TIG welding (tungsten argon arc welding) ke mokhoa oa ho cheseletsa oo Ar e hloekileng e sebelisoang e le khase e sireletsang le li-electrode tsa tungsten li sebelisoa e le li-electrode.TIG wire welding e fanoa ka likhoele tse otlolohileng tsa bolelele bo itseng (hangata lm).Welding ea arc e sirelelitsoeng ka khase e inert e sebelisa...Bala haholoanyane»

-

Mosebetsi oa ho tjheseletsa o kenyelletsa masimo a mangata a indasteri, mosi oa welding ke e 'ngoe ea likotsi tse atileng haholo tsa mosebetsi oa ho cheselletsa.Mosi oa welding o ts'ebetsong ea ho tjheseletsa ha molamu oa welding le likarolo tsa welding li kopana, ha ho chesa mocheso o phahameng ho hlahisa mofuta oa mosi, mosi ona o na le manganese ...Bala haholoanyane»

-

Metsoalle e Ratehang!Thabo e kholo ho uena selemong se tlang.E se eka litakatso tse futhumetseng, mehopolo e thabisang le litumeliso tse nang le botsoalle li tle Selemong se Secha 'me li lule le uena selemo kaofela!electrode,electrodes, welding, welding electrode, welding electrode, welding rod, welding rods, welding electrode price, electrode...Bala haholoanyane»

-

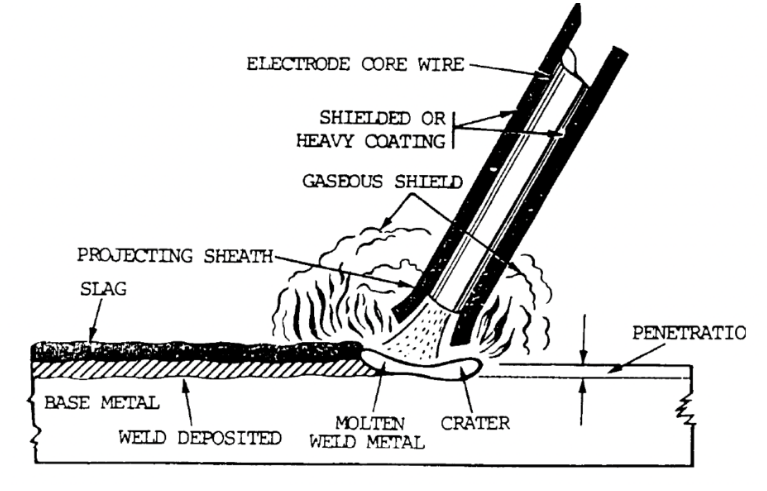

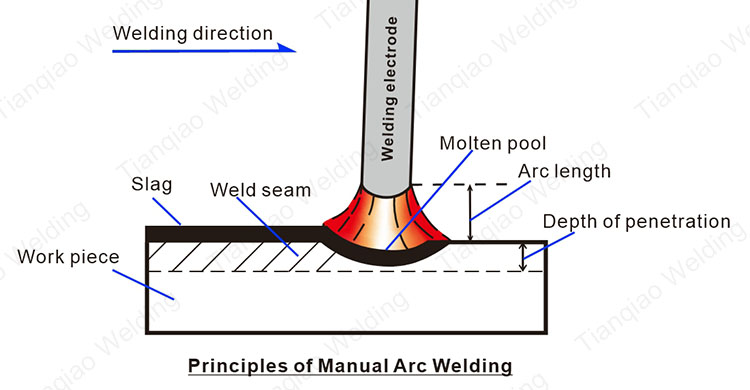

SMAW, eo hape e tsejoang ka hore ke electrode arc welding, ke mokhoa oa ho tjheseletsa oa fusion oo arc e hlahisoang ke electrode le likarolo tsa welding li qhibilihisoa ke mocheso oa arc.Ke mokhoa o sebelisoang haholo le o tloaelehileng oa ho tjheseletsa ha joale.Arc ke ts'ebetso ea ho tsamaisa moea.The welding arc ke ...Bala haholoanyane»

-

Nahana ka thepa ea 'mele, thepa ea mechine le lik'hemik'hale tsa lisebelisoa tsa weld 1. Ts'ebetso ea tšepe ea mohaho, ka kakaretso e nahane ka molao-motheo oa matla a lekanang, khetha ho finyella litlhoko tsa thepa ea mochine oa thepa e kopanetsoeng ea welding.2. Bakeng sa khabone e tlase ...Bala haholoanyane»

-

Tungsten argon arc welding ke mofuta oa mokhoa oa ho cheselletsa arc o sebelisang argon kapa argon e ngata ea khase e le tšireletso le electrode ea tungsten joalo ka electrode, e bitsoang GTAW(Gas Tungsten Arc Weld) kapa TIG(Tungsten Inert Gas Welding) ka bokhutšoanyane.Nakong ea welding, khase e sireletsang e lula e fafatsoa ...Bala haholoanyane»

-

Mosebetsi oa ho lokisa pele ho tjheseletsa o bohlokoa joalo ka ts'ebetso ea welding, e amanang ka kotloloho le boleng le phello ea sehlahisoa se felileng.1. Electrode drying Sepheo sa ho omisa electrode pele ho welding ke ho tlosa mongobo ka har'a electrode e metsi le ho fokotsa hy ...Bala haholoanyane»