The barbotage phetha karolo e rarahaneng metallurgical karabelo le liphetoho 'meleng le lik'hemik'hale tshebetso tjheseletsa, eo ha e le hantle hlōla mathata a tjheseletsa photo photo photo photo eleketrode, kahoo barbotage ke e' ngoe ea lintlha tse ka sehloohong ho fumana hore na boleng ba tšepe weld.

Ho roala ka elektrode:E bua ka barbotage mposo ya thepa e ntle granular le thepa e fapaneng 'meleng le lik'hemik'hale ka mokhoa o tšoanang a tlotsitsoeng holim'a tjheseletsa mantlha.

Karolo eatjheseletsa electrodeho roala:Ts'ebetsong ea welding, e theha slag e nang le sebaka se nepahetseng sa ho qhibiliha, viscosity, density, alkalinity le lisebelisoa tse ling tsa 'mele le tsa lik'hemik'hale, ho etsa bonnete ba hore mollo oa arc o tsitsitse, o etsa hore tšepe ea marotholi e fetohe habonolo, e thehe moea o potolohileng sebaka sa arc le letamo le qhibilihisitsoeng ho sireletsa. sebaka sa welding, 'me u fumane sebopeho se setle le ts'ebetso ea weld.Ka ho eketsa deoxidizer, motsoako oa motsoako kapa likarolo tse itseng tsa phofo ea tšepe ho koahela, e ka boela ea finyella litlhoko tsa ts'ebetso ea tšepe ea weld kapa ea ntlafatsa ts'ebetso ea ho qhibiliha.

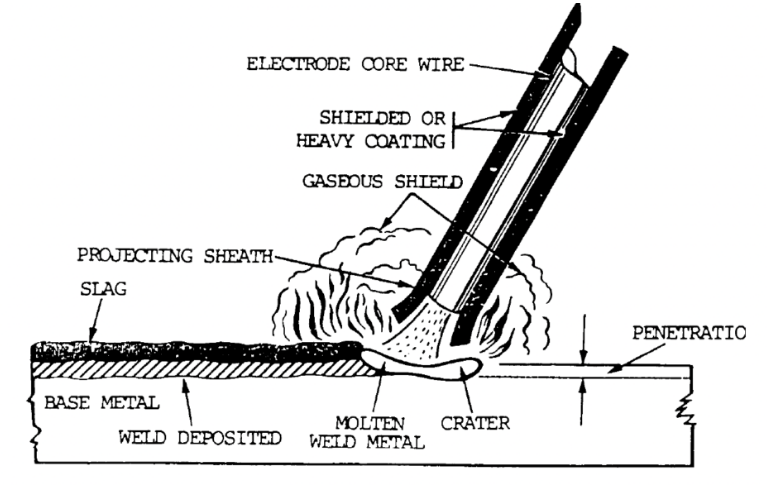

Molao-motheo oa li-electrode arc welding:

1. Letlalo la meriana

2. Weld mantlha

3. Sireletsa khase

4: Leq

5. Letamo le qhibilihisitsoeng

6. Thepa ea motheo

7. Weld

8. Welding slag

9. Slag

10. Qhibiliha marotholi

Lisebelisoa tse sa tšoaneng tse tala ho ea ka karolo ea tsona ea ho roala li-electrode li ka aroloa ka:

(1) Arc stabilizer

Mosebetsi o ka sehloohong ke ho etsa hore electrode e be bonolo ho qala arc le ho boloka mollo o tsitsitseng oa arc ts'ebetsong ea welding.Joalo ka lisebelisoa tse tala tsa arc stabilizer ke tse ling tse nang le palo e itseng ea lisebelisoa tse tlase tsa ionization tse ka bang bonolo, joalo ka feldspar, sodium silicate, rutile, titanium dioxide, marble, mica, ilmenite, ilmenite e fokotsehileng joalo-joalo.

(2) Setsi sa ho etsa khase

Tlas'a ketso ea mocheso o phahameng oa arc decomposition khase, ho etsa sepakapaka se sireletsang, ho sireletsa arc le tšepe e qhibilihisitsoeng, ho thibela ho kenella ha oksijene le naetrojene moeeng o potolohileng.Lintho tse sebelisoang ka tloaelo ho etsa khase ke carbonate (e kang marble, dolomite, rhombic acid, barium carbonate, joalo-joalo) le lintho tse phelang (tse kang phofo ea lehong, starch, cellulose, resin, joalo-joalo).

(3) Deoxidizer (eo hape e tsejoang e le moemeli oa ho fokotsa)

Likahare tsa oksijene ka tšepe ea weld li ka fokotsoa mme ts'ebetso ea tšepe ea weld e ka ntlafatsoa ka karabelo ea lik'hemik'hale ea metallurgic ts'ebetsong ea welding.Deoxidizer haholo-holo e na le likarolo tsa motsoako oa tšepe le phofo ea tšepe e amanang haholo le oksijene.Deoxidizer e sebelisoang hangata ke ferromanganese, ferrosilicon, ferrotitanium, ferroaluminum, silicon calcium alloy, joalo-joalo.

(4) Plasticizer

Mosebetsi oa eona o ka sehloohong ke ho ntlafatsa polasetiki, elasticity le fluidity ha ho ntse ho hatelloa li-electrode coating , ho ntlafatsa boleng ba ho roala ha electrode, e le hore sebaka se boreleli sa ho roala ha electrode se se ke sa phunyeha.Hangata, khetha elasticity e itseng, e thellang kapa e monyang ka mor'a litšobotsi tse itseng tsa katoloso ea thepa, joalo ka mica, seretse se tšoeu, titanium dioxide, talc, khalase ea metsi e tiileng, selulose, joalo-joalo.

(5) Moemeli oa motsoako

E sebelisetsoa ho lefella ho chesoa ha likarolo tsa alloying ts'ebetsong ea ho cheselletsa le ho fetisetsa lisebelisoa tsa alloying ho weld, e le ho etsa bonnete ba hore lik'hemik'hale le thepa ea tšepe ea weld.Ho ea ka tlhoko ea ho khetha mefuta e fapaneng ea li-ferroalloys (tse kang ferromanganese, ferrosilicon, ferrochrome, tšepe le tšepe, ferric vanadium, ferric niobium, ferric boron, ferrosilicon e sa tloaelehang ea lefatše, joalo-joalo) kapa tšepe e hloekileng (joalo ka tšepe ea manganese, tšepe ea chromium). , phofshoana ea nickel, phofo ea tungsten, joalo-joalo).

(6) Moemeli oa ho etsa li-slag

Ho tjheseletsa ho ka theha thepa e itseng ea 'mele le ea lik'hemik'hale ea slag e qhibilihisitsoeng, sireletsa lerotholi la welding le tšepe e qhibilihisitsoeng ea letamo, ho ntlafatsa sebopeho sa weld, joalo ka ha moemeli oa slagging oa lisebelisoa tse tala ke marble, fluorite, dolomite, magnesia, feldspar, seretse se tšoeu, mica, quartz. , rutile, titanium dioxide, ilmenite, joalo-joalo.

(7) Setlamo

Thepa ea ho roala e tlamahane ka thata ho setsi sa welding, 'me seaparo sa electrode se na le matla a itseng ka mor'a ho omisa.Ts'ebetsong ea ho cheselletsa metallurgy, ha ho na phello e kotsi ho letamo la weld le tšepe ea weld.Li-binders tse sebelisoang hangata ke sodium silicate (potasiamo, sodium le silicate e tsoakiloeng ea sodium) le phenolic resin, gum, joalo-joalo.

Nako ea poso: May-04-2023