Electrode arc welding ke mokhoa o sebelisoang haholo oa ho tjheseletsa tlhahiso ea indasteri.Tšepe e lokelang ho chesetsoa ke palo e le 'ngoe,' me electrode ke palo e 'ngoe.Ha lipalo tse peli li atamelane, ho etsoa arc.Mocheso o hlahisoang ke ho tsoa ha arc (oo hangata o tsejoang e le arc combustion) o sebelisoa ho hokahanya eleketrode le li-workpieces tse qhibilihang ebe li theha weld ka mor'a ho kokobetsa, e le ho fumana ts'ebetso ea ho tjheseletsa ka motsoako o matla.

Setšoantšo sa 1. Histori ea welding

Histori e khuts'oane

Ka mor’a liteko tse ngata tsa ho cheselletsa litšepe mathoasong a lekholo la bo19 la lilemo, monna oa Lenyesemane ea bitsoang Willard o ile a qala ho fumana tokelo ea molao ea ho cheselletsa litšepe ka 1865. O ile a sebelisa motlakase oa motlakase ho feta likotoana tse peli tse nyenyane tsa tšepe ho li kopanya ka katleho, ’me hoo e ka bang lilemo tse mashome a mabeli hamorao, monna oa Lerussia. ea bitsoang Bernard o ile a fumana patent bakeng sa ts'ebetso ea ho cheselletsa li-arc.O ile a boloka arc pakeng tsa palo ea carbon le li-workpieces.Ha arc e ne e sebelisoa ka letsoho ka lenonyeletso la li-workpieces, li-workpieces tse lokelang ho chesetsoa li ne li kopanngoa hammoho.Lilemong tsa bo-1890, tšepe e tiileng e ile ea ntlafatsoa e le electrode, e neng e jeoa ka letamong le entsoeng ka ho qhibilihisoa 'me ea fetoha karolo ea tšepe ea weld.Leha ho le joalo, oksijene le naetrojene moeeng li ile tsa etsa li-oxide tse kotsi le nitride tšepeng e chesehang., Kahoo e lebisang ho boleng bo bobe ba welding.

Mathoasong a lekholo la bo20 la lilemo, bohlokoa ba ho sireletsa arc ho qoba ho kenella moeeng bo 'nile ba phethahala,' me tšebeliso ea mocheso oa arc ho senya seaparo ka har'a electrode ea tšireletso ea khase e sireletsang e ile ea e-ba mokhoa o molemo ka ho fetisisa.Bohareng ba lilemo tsa bo-1920, ho ile ha etsoa electrode e koahetsoeng, e ileng ea ntlafatsa haholo boleng ba tšepe e cheselitsoeng.Ka nako e ts'oanang, e kanna ea ba phetoho ea bohlokoa ka ho fetisisa ea welding ea arc.Lisebelisoa tsa mantlha ts'ebetsong ea welding li kenyelletsa mochini oa welding oa motlakase, lithaole tsa welding le mask a sefahleho.

Setšoantšo sa 2. Molao-motheo oa welding

Setšoantšo sa 2. Molao-motheo oa welding

Molao-motheo

The welding arc e tsamaisoa ke mohloli oa matla oa welding.Tlas'a ketso ea motlakase o itseng, ketsahalo e matla le e tšoarellang nako e telele e etsahala pakeng tsa electrode (le qetellong ea terata ea welding kapa molamu oa welding) le workpiece.Ntho ea bohlokoa ea li-welding arc ke khase e tsamaisang khase, ke hore, khase e sa nke lehlakore sebakeng seo arc e leng ho sona e qhibiliha ho ba li-ion tse ntle tse nang le lisebelisoa tse ntle le li-electrone tse nang le matla a fosahetseng tlas'a ketso ea motlakase o itseng, o bitsoang ionization.Likaroloana tsena tse peli tse qosoang li lebisitsoe ho lipalo tse peli.Motsamao oa tataiso o etsa hore khase ea lehae e tsamaise motlakase ho etsa arc.Arc ea motlakase e fetola matla a motlakase hore e be mocheso, o futhumatsang le ho qhibilihisa tšepe ho etsa lenonyeletso le cheselitsoeng.

Ka mor'a hore arc e susumelletsehe ho "chesa", mokhoa oa ho qhala ka boeona o ka hlahisa likaroloana tse qosoang tse hlokahalang ho boloka ho tsoa, e leng ntho e ikemetseng ea ho itokolla.'Me ts'ebetso ea ho ntša arc e na le matla a tlaase, hona joale, mocheso o phahameng le luminescence e matla.Ka ts'ebetso ena, matla a motlakase a fetoloa mocheso, motlakase le matla a bobebe.Welding haholo-holo e sebelisa matla a eona a mocheso le mochini ho fihlela sepheo sa ho hokahanya litšepe.

Nakong ea welding, arc e chesa pakeng tsa molamu oa welding le li-workpieces tsa welding, e qhibilihisa li-workpieces le motsoako oa electrode ho etsa letamo le qhibilihisitsoeng.Ka nako e ts'oanang, ho roala ha electrode ho boetse ho qhibiliha, 'me ho etsahala lik'hemik'hale ho theha slag le khase, e sireletsang qetello ea electrode, marotholi, letamo le qhibilihisitsoeng le tšepe ea weld e phahameng ea mocheso.

Sehlopha se seholo

Mekhoa e tloaelehileng ea welding ea arc haholo-holo e kenyelletsa Shielded Metal Arc Welding (SMAW), Submerged Arc Welding (SAW), Gas Tungsten Arc Weld (GTAW kapa TIG welding), Plasma Arc Welding (PAW) le Gas Metal Arc Welding (GMAW, MIG kapa MAG welding). ) joalo-joalo.

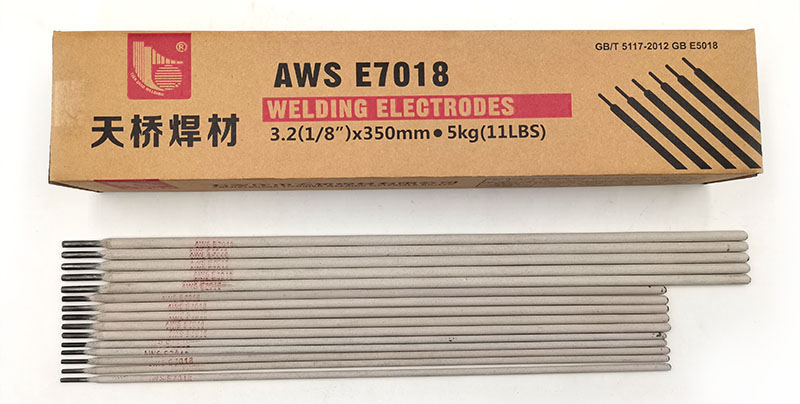

Setšoantšo sa 3. E7018 welding electrode

Shielded Metal Arc Welding (SMAW)

Shielded tšepe arc tjheseletsa sebelisa eleketrode le workpiece e le li-electrode tse peli, 'me mocheso le ho letsa matla a arc li sebelisoa ho ea sebakeng sa heno qhibilihisa workpiece nakong tjheseletsa.Ka nako e ts'oanang, tlas'a ts'ebetso ea mocheso oa arc, qetellong ea electrode e qhibiliha ho etsa lerotholi, 'me workpiece e qhibiliha ka mokhoa o itseng ho etsa sekoti sa oval se tletseng tšepe ea metsi.Mokelikeli o entsoeng ka tšepe o qhibilihisitsoeng le lerotholi la sesebelisoa sa mosebetsi li etsa letamo le qhibilihisitsoeng.Nakong ea ts'ebetso ea ho tjheseletsa, ho roala le ho se tšepe ke li-inclusions tse qhibilihisang 'me li theha ntho e seng ea tšepe e koahelang holim'a tjheseletsa ka liphetoho tsa lik'hemik'hale tse bitsoang slag.Ha arc e ntse e sisinyeha, letamo le entsoeng ka ho qhibilihisoa lea pholile ebe le tiea ho etsa cheseletso.Re na le li-electrode tse fapaneng tsa welding bakeng sa SMAW, mefuta e tsebahalang haholo keE6010, E6011, E6013, E7016, E7018, le bakeng sats'epe e sa beng le mabali, tšepe ea tšepe, kahohle ka thataetc.

Setšoantšo sa 4. Ho tjheseletsa arc ka metsing

Setšoantšo sa 4. Ho tjheseletsa arc ka metsing

Arc Welding e ka tlas'a metsi (SAW)

Submerged arc welding ke mokhoa oo arc e chesoang ka tlas'a lesela la flux bakeng sa welding.Electrode ea tšepe e sebelisoang ho tjheseletsa arc ka tlas'a metsi ke terata e se nang letho e kenang ka boeona ntle le tšitiso.Ka kakaretso, trolley ea welding kapa lisebelisoa tse ling tsa mochini le tsa motlakase li sebelisoa ho hlokomela motsamao o ikemetseng oa arc nakong ea ts'ebetso ea welding.The arc ea submered arc welding e cha ka tlas'a granular flux.Mocheso oa arc oa qhibiliha 'me o fetoha mouoane likarolo tse etsoang ka ho toba ke arc ea workpiece, qetellong ea terata ea welding le flux,' me mouoane oa tšepe le phallo e fetoha mouoane ho etsa sekoti se koetsoeng ho pota-potile arc.Chesa lesoba lena.Sekoti se pota-potiloe ke filimi ea slag e entsoeng ka slag e hlahisoang ke ho qhibiliha ha flux.Filimi ena ea slag ha e arole hantle feela moea ho tloha ho kopana le arc le letamo le entsoeng ka ho qhibilihisoa, empa hape e thibela arc hore e se ke ea tsoa.Mohala oa ho tjheseletsa o futhumetseng mme o qhibilihisoa ke arc o oela ka mokhoa oa marotholi 'me o kopana le tšepe e qhibilihisitsoeng ho etsa letamo le qhibilihisitsoeng.Letlapa le lenyenyane le teteaneng le phaphametse letamong le entsoeng ka ho qhibilihisoa.Ntle le ho itšehla thajana le ts'ireletso ea tšepe ea letamo le qhibilihisitsoeng, slag e qhibilihisitsoeng e boetse e na le karabelo ea metallurgic ka tšepe ea letamo le qhibilihisitsoeng nakong ea ts'ebetso ea welding, ka hona e ama sebopeho sa lik'hemik'hale tsa tšepe ea weld.Arc e ea pele, 'me tšepe e qhibilihisitsoeng ea letamo e theoha butle-butle ebe e phatsima ho etsa weld.Ka mor'a hore slag e qhibilihisitsoeng e phaphametseng karolong e ka holimo ea letamo le entsoeng ka ho qhibilihisoa e pholile, ho thehoa lekhapetla la slag ho tsoela pele ho sireletsa weld mocheso o phahameng le ho thibela hore e se ke ea e-ba oxidized.Re fana ka phallo ea SAW,SJ101,SJ301,SJ302

Setšoantšo sa 5. Khase ea Tungsten Arc Weld-TIG

Setšoantšo sa 5. Khase ea Tungsten Arc Weld-TIG

Gas Tungsten Arc Weld/Tungsten Inert Gas Welding (GTAW kapa TIG)

TIG welding e bolela mokhoa oa ho cheselletsa arc o sebelisang tungsten kapa tungsten alloy (thorium tungsten, cerium tungsten, joalo-joalo) e le electrode le argon e le khase e sireletsang, e bitsoang TIG welding kapa GTAW welding.Nakong ea welding, tšepe ea ho tlatsa e ka eketsoa kapa ea se ke ea eketsoa ho latela mofuta oa groove oa weld le ts'ebetso ea tšepe ea weld.Hangata tšepe ea ho tlatsa e kenngoa ho tloha ka pele ho arc.Ka lebaka la bokhabane ba aluminium-magnesium le lisebelisoa tsa eona tsa alloy, welding ea AC tungsten arc ea hlokahala bakeng sa welding, 'me welding ea DC tungsten arc e sebelisetsoa lisebelisoa tse ling tsa tšepe.E le ho laola ho kenya mocheso, pulsed argon tungsten arc welding e sebelisoa haholo le ho feta.Haholo-holo sebelisoa lithapo tjheseletsa TIG keAWS ER70S-6, ER80S-G,ER4043,ER5356,HS221le joalo-joalo.

Setšoantšo sa 5. Plasma Arc Welding

Setšoantšo sa 5. Plasma Arc Welding

Plasma Arc Welding (PAW)

Plasma arc ke mofuta o khethehileng oa arc.The arc e boetse e le tungsten kapa tungsten alloy (thorium tungsten, cerium tungsten, joalo-joalo) e le electrode ea arc, e sebelisa argon e le khase e sireletsang, empa motlakase oa tungsten ha o tsoe ka molomong, empa o hula ka hare ho molomo. e pholile ka metsi, e tsejoang hape ka hore ke nozzle e pholileng ka metsi.Khase ea inert e arotsoe likarolo tse peli, karolo e 'ngoe ke khase e nkiloeng pakeng tsa electrode ea tungsten le nozzle e pholileng ka metsi, e bitsoang ion gas;karolo e 'ngoe ke khase e nkiloeng pakeng tsa molomo o pholileng oa metsi le khase e sireletsang ea khase, e bitsoang Shielding gas, e sebelisang plasma arc e le mohloli oa mocheso bakeng sa ho cheselletsa, ho itšeha, ho fafatsa, ho pota-pota, joalo-joalo.

Setšoantšo sa 5 Metal-Inert Gas Welding

Setšoantšo sa 5 Metal-Inert Gas Welding

Metal Inert Gas Welding (MIG)

Ho tjheseletsa MIG ho bolela hore terata e tjheseletsang e nka sebaka sa eleketrode ya tungsten.Khoele ea ho tjheseletsa ka boeona ke e 'ngoe ea lipalo tsa arc, e bapala karolo ea ho tsamaisa motlakase le ho roala,' me ka nako e le 'ngoe e le thepa ea ho tlatsa, e tsoelang pele ho qhibiliha le ho tlatsoa ka weld tlas'a ketso ea arc.Khase e sireletsang e atisang ho sebelisoa ho pota-pota arc e ka ba khase ea inert Ar, khase e sebetsang CO2, kapa Ar+CO2khase e tsoakiloeng.MIG welding e sebelisang Ar e le khase e sireletsang e bitsoa welding MIG;MIG welding e sebelisang CO2joalo ka ha khase e sireletsang e bitsoa CO2tjheseletsa.Li-MIG tse tsebahalang haholo keAWS ER70S-6, ER80S-G.

Nako ea poso: Aug-17-2021