Shielded Metal Arc Welding (e khutsufalitsoeng e le SMAW).Molao-motheo ke: arc e hlahisoa pakeng tsa electrode e koahetsoeng le tšepe ea motheo, le mokhoa oa ho tjheseletsa o sebelisa mocheso oa arc ho qhibiliha electrode le tšepe ea motheo.Lera le ka ntle la eleketrode le koahetsoe ke welding flux 'me le qhibiliha ha le pepesehile mocheso, o nang le mesebetsi ea ho tsitsisa arc, ho etsa slag, deoxidizing le ho hloekisa.Hobane e hloka lisebelisoa tse bonolo le ts'ebetso e bonolo, e ka chesetsoa habonolo ho li-welds tse entsoeng ke maemo a fapaneng le manonyeletso a fapaneng sebakeng.Ka hona, e ntse e sebelisoa haholo kajeno.

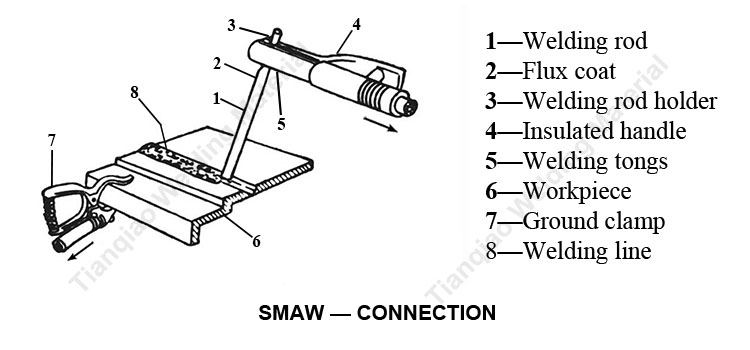

Setšoantšo sa 1: Sielded Metal Arc Welding-connection

Manual arc welding e bontšoa setšoantšong:

Pele ho tjheseletsa, hokela sesebediswa se tjheseletsang le masela a tjheseletsa dipaleng tse pedi tsa mochini o tjheseletsang tjheseletsa mme o tlamelle molamu wa welding ka masela a tjheseletsang.Nakong ea welding, molamu oa welding le workpiece li kopana hang-hang, li etsa potoloho e khutšoanyane, ebe li aroloa ka sebaka se itseng (hoo e ka bang 2-4mm), 'me arc e chesoa.

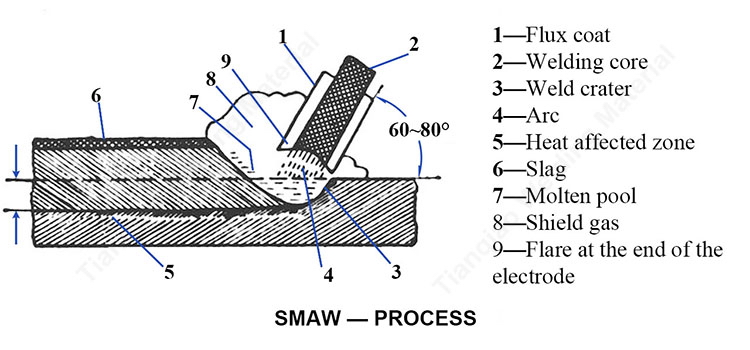

Setšoantšo sa 2: Tšireletso ea Metal Arc Welding-ts'ebetso

Mosebetsi o ka tlas'a arc hang-hang oa qhibiliha ho etsa letamo le qhibilihisitsoeng la semi-oval.Ka mor'a hore setlolo sa electrode se qhibilihe, karolo ea eona e fetoha khase e pota-potileng arc ho e arola moeeng, kahoo e sireletsa tšepe ea mokelikeli ho tloha oksijene le naetrojene;karolo e 'ngoe ea eona e fetoha slag e entsoeng ka ho qhibilihisoa, kapa e fafalitsoeng ka har'a letamo le entsoeng ka ho qhibilihisoa feela, kapa e qhibilihisoa ka motheo Marotholi a qhibilihileng a tšepe e metsi a fafatsoa letamong le qhibilihileng hammoho.

Ka har'a arc le letamo le entsoeng ka ho qhibilihisoa, tšepe ea metsi, slag le khase ea arc li tla ba le liphetoho tse itseng tsa 'mele le tsa lik'hemik'hale, tse kang ho qhibiliha ha khase ka har'a tšepe ea metsi le karabelo ea ho fokotsa oxidation.Khase le slag ka letamong le entsoeng ka ho qhibilihisoa li phaphamala ka lebaka la boima ba eona bo bobebe.Ha arc e tlosoa, mocheso o theoha 'me tšepe le slag li tla tiisa ka ho latellana.Ka tsela ena, likotoana tse peli tsa tšepe li kopantsoe ke tšepe e qhibilihisitsoeng le e entsoeng ka kristale.Hobane shrinkage ea slag e fapane le ea tšepe, e tla thella holim'a khetla ea slag le moeli oa tšepe, 'me khetla ea slag e ka oa ka tsela e iketsang, kapa ea oa ka mor'a ho kokota,' me tšepe ea weld seam e nang le sekala sa litlhapi. e ka pepesoa.

Thepa e ka sehloohong ea li-arc welding ke mochini oa welding oa motlakase.Mochini oa tjheseletsa oa motlakase ke mohloli oa matla o hlahisang li-welding arc, 'me ho na le mefuta e' meli ea AC le DC.Hona joale, ho na le mefuta e mengata ea mechine ea ho tjheseletsa ea motlakase e hlahisoang Chaena, e ka aroloa ka mechine ea ho tjheseletsa ea motlakase ea AC le mechine ea motlakase ea DC ea motlakase ho ea ka sebopeho sa eona.

Ho na le mekhoa e 'meli e fapaneng ea khokahano bakeng sa mochini oa welding oa DC.Ha electrode e amana le electrode e mpe 'me mosebetsi o kopantsoe le electrode e ntle, ke mokhoa o motle oa ho hokahanya;se fapaneng ke mokhoa oa ho hokahana ka morao.Ka kakaretso, ha tjheseletsa ka alkaline low-hydrogen electrode (joalo kaE7018, E7016), e le ho etsa hore arc e chese ka mokhoa o tsitsitseng, ho laetsoe ho sebelisa mokhoa oa ho kopanya oa DC reverse;ha u sebelisa electrode ea acid (joalo kaE6013, J422) ho cheseletsa lipoleiti tsa tšepe tse teteaneng, mokhoa oa ho hokahanya pele o sebelisoa, hobane karolo ea anode Mocheso o phahame ho feta karolo ea cathode, 'me mokhoa oa ho hokahanya o ka pele o ka fumana botebo bo boholo ba ho kenella;ha ho tjheseletsa lipoleiti tsa tšepe tse tšesaane le litšepe tse se nang ferrous, ho sebelisoa mokhoa oa ho hokahanya o reverse.Ha tjheseletsa ka alternating hona joale, kaha polarity e fetoha ka tsela e fapaneng, ha ho hlokahale hore u khethe khokahano ea polarity.

Thepa ea welding bakeng sa ho tjheseletsa ka letsoho ke molamu oa welding oa motlakase, o nang le motheo oa tšepe le koae ka ntle ho mokokotlo oa tšepe (Bona hape.Sebopeho sa electrode ea welding).

Mokotla oa welding

Karolo ea motheo oa tšepe (welding core) ke haholo-holo ho tsamaisa motlakase le ho etsa tšepe e behiloeng ka sebopeho se itseng qetellong ea electrode.Mokotla oa welding o ka etsoa ka litšepe tse fapaneng.Sebopeho sa motheo oa welding se ama ka ho toba sebopeho le ts'ebetso ea tšepe e behiloeng.Ka hona, motheo oa welding oa hlokahala ho fokotsa litaba tsa lintho tse kotsi.Ntle le ho fokotsa S le P, lithupa tse ling tsa welding li hloka hore mokokotlo oa welding o laole As, Sb, Sn le likarolo tse ling.

Setšoantšo sa 3: Tianqiao welding electrode E6013

Seaparo sa flux

Ho roala ha electrode ho ka boela ha bitsoa pente.Morero o ka sehloohong oa ho e roala mokokotlong ke ho tsamaisa ts'ebetso ea welding le ho etsa bonnete ba hore tšepe e behiloeng e na le sebopeho le ts'ebetso e itseng.Liaparo tsa elektrode li ka kopanngoa le makholo a lihlahisoa tse tala tse kang oxides, carbonates, silicates, organics, fluorides, ferroalloys le lihlahisoa tsa lik'hemik'hale ho latela tekanyo e itseng ea foromo.Lisebelisoa tse fapaneng tse tala li ka aroloa ka mekhahlelo e latelang ho latela karolo ea tsona ho roala li-electrode:

1. Stabilizer e etsa hore electrode e be bonolo ho qala arc mme e ka boloka arc e tuka ka mokhoa o tsitsitseng nakong ea ts'ebetso ea welding.Ntho efe kapa efe e bonolo ho ionize e ka tsitsisa arc.Ka kakaretso, ho sebelisoa metsoako ea tšepe ea alkali le tšepe ea lefatše ea alkaline, joalo ka potassium carbonate, sodium carbonate, marble, joalo-joalo.

2. Setsi sa ho etsa li-slag se ka etsa slag e entsoeng ka ho qhibilihisoa ka thepa e itseng ea 'mele le lik'hemik'hale nakong ea ho cheselletsa, ho koahela bokaholimo ba tšepe e qhibilihisitsoeng, ho sireletsa letamo la ho cheselletsa le ho ntlafatsa sebopeho sa weld.

3. Deoxidizer ka karabelo ea lik'hemik'hale ea metallurgical ts'ebetsong ea welding ho fokotsa oksijene ka har'a tšepe ea weld le ho ntlafatsa thepa ea mochini oa weld.Li-deoxidizer tse ka sehloohong ke ferromanganese, ferrosilicon, le ferro-titanium.

4. Setsi sa ho hlahisa khase se ka arola le ho lokolla khase tlas'a ketso ea mocheso o phahameng oa arc ho sireletsa arc le letamo le qhibilihisitsoeng le ho thibela ho kenella ha oksijene le naetrojene moeeng o potolohileng.

5. Alloying agent E sebelisetsoa ho lefella ho chesoa ha likarolo tsa alloy le phetoho ea likarolo tsa alloy ho weld nakong ea ts'ebetso ea welding ho netefatsa hore tšepe ea weld e fumana lik'hemik'hale tse hlokahalang le ts'ebetso.

6. Plasticizing Lubricant Eketsa polasetiki, ho thella le ho phalla ha phofo ea ho roala ka har'a ts'ebetso ea ho hatisa molamu oa welding ho ntlafatsa boleng ba khatello ea molamu oa welding le ho fokotsa eccentricity.

7. Li-adhesives Etsa hore phofo ea ho roala e be le viscosity e itseng nakong ea ts'ebetso ea ho roala ha compression, e ka khomarela ka tieo le mokokotlo oa welding, 'me e etsa hore ho roala ha molamu oa welding ho be le matla a itseng ka mor'a ho omisa.

Nako ea poso: Jul-27-2021