The tjheseletsa mesaletsa khatello ea kelello e bakoa ke ho se leka-lekane mocheso kabo ea tjheseletsa bakoang ke tjheseletsa, ho atolosoa mogote le contraction ea tšepe tjheseletsa, joalo-joalo, kahoo tjheseletsa kaho tla ke keng ea qojoa hlahisa khatello ea kelello masala.

Mokhoa o tloaelehileng ka ho fetisisa oa ho felisa khatello ea kelello e setseng ke mocheso o phahameng oa mocheso, ke hore, ho futhumatsa tjheseletsa ho mocheso o itseng le ho o tšoara ka nako e itseng ka sebōpi sa phekolo ea mocheso, le ho sebelisa phokotso ea moeli oa lihlahisoa oa thepa. ka mocheso o phahameng ho etsa hore polasetiki e phalle libakeng tse nang le khatello e phahameng ea ka hare.The deformation elastic butle-butle ea fokotseha, 'me deformation ea polasetiki butle-butle e eketseha ho fokotsa khatello ea maikutlo.

1.Khetho ea mokhoa oa ho phekola mocheso

Phello ea ka mor'a tjheseletsa mocheso kalafo ka tensile matla le creep moeli oa tšepe e amana le mocheso kalafo mocheso le ho tšoara nako.Phello ea phekolo ea mocheso ka mor'a ho cheseha ka matla a ts'usumetso ea tšepe ea weld e fapana le mefuta e fapaneng ea tšepe.

Phekolo ea mocheso ka mor'a weld hangata e amohela mocheso o le mong oa mocheso o phahameng kapa ho tloaeleha hammoho le mocheso o phahameng oa mocheso.Bakeng sa manonyeletso a ho cheselletsa khase, ho amoheloa ho tloaelehileng le mocheso o phahameng oa mocheso.Lebaka ke hobane lithollo tsa seam welding ea khase le sebaka se anngoeng ke mocheso li mahoashe, 'me lithollo li hloka ho hloekisoa, kahoo kalafo e tloaelehileng e amoheloa.

Leha ho le joalo, tloaelo e le 'ngoe e ke ke ea felisa khatello ea kelello e setseng, kahoo mocheso o phahameng oa mocheso o hlokahalang ho felisa khatello ea kelello.Mocheso o le mong oa mocheso o bohareng o loketse feela ho kopanya le ho tjheseletsa ha lijana tse kholo tse tloaelehileng tsa tšepe tse tlaase tsa carbon tse bokelletsoeng setšeng, 'me morero oa eona ke ho finyella ho felisa khatello ea kelello e setseng le dehydrogenation.

Maemong a mangata, ho sebelisoa mocheso o le mong o phahameng oa mocheso.Ho futhumatsa le ho pholile ha phekolo ea mocheso ha hoa lokela ho potlaka haholo, 'me marako a ka hare le a ka ntle a lokela ho tšoana.

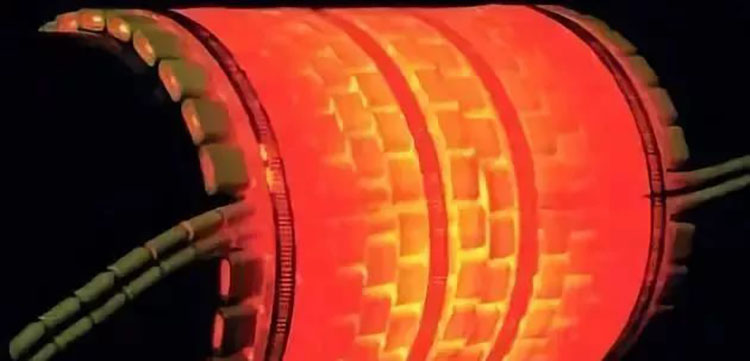

2.Mekhoa ea phekolo ea mocheso e sebelisoang lijaneng tsa khatello

Ho na le mefuta e 'meli ea mekhoa ea phekolo ea mocheso bakeng sa likepe tsa khatello: e' ngoe ke phekolo ea mocheso ho ntlafatsa thepa ea mechine;e 'ngoe ke post-weld heat treatment (PWHT).Ha re bua ka mokhoa o pharaletseng, phekolo ea mocheso oa post-weld ke phekolo ea mocheso ea sebaka se cheselitsoeng kapa likarolo tse entsoeng ka mor'a hore workpiece e kenngoe.

Likahare tse ikhethileng li kenyelletsa ho imolla khatello ea maikutlo, ho koala ka botlalo, tharollo e tiileng, ho tloaeleha, ho tloaeleha le ho futhumatsa, ho futhumatsa, ho fokotsa khatello ea mocheso o tlase, kalafo ea mocheso oa pula, jj.

Ka kutloisiso e moqotetsane, kalafo ea mocheso oa post-weld e bua feela ka ho fokotsa khatello ea maikutlo, ke hore, molemong oa ho ntlafatsa ts'ebetso ea sebaka sa welding le ho felisa litlamorao tse mpe joalo ka khatello e setseng ea welding, e le ho futhumatsa sebaka sa welding ka mokhoa o ts'oanang le ka botlalo. le likarolo tse amanang le tlas'a tšepe mohato phetoho 2 mocheso ntlha , 'me joale tshebetso ya junifomo tsidifatso.Maemong a mangata phekolo ea mocheso oa postweld eo ho buisanoang ka eona ke phekolo ea mocheso oa postweld.

3.Morero oa kalafo ea mocheso oa post weld

(1).Phomola tjheseletsa khatello e setseng.

(2).Tsitsisa sebopeho le boholo ba sebopeho le ho fokotsa ho khopama.

(3).Ntlafatsa ts'ebetso ea tšepe ea motheo le manonyeletso a cheselitsoeng, ho kenyelletsa:

a.Ntlafatsa polasetiki ea tšepe ea weld.

b.Fokotsa ho thatafala ha sebaka se amehileng ke mocheso.

c.Ntlafatsa ho tiea ha fracture.

d.Ntlafatsa matla a mokhathala.

e.Khutlisa kapa eketsa matla a chai a fokotsehileng ka ho etsa serame.

(4).Ntlafatsa bokhoni ba ho hanela khatello ea maikutlo.

(5).Ho tsoela pele ho lokolla likhase tse kotsi ka tšepe ea weld, haholo-holo hydrogen, ho thibela ho hlaha ha mapetsong a liehang.

4.Kahlolo ea tlhoko ea PWHT

Ho sa tsotellehe hore na phekolo ea mocheso oa post-weld e hlokahalang bakeng sa sekepe sa khatello e lokela ho hlalosoa ka ho hlaka moralong, e hlokehang ke khoutu ea moralo oa sekepe sa khatello ea hona joale.

Bakeng sa likepe tsa khatello tse cheselitsoeng, ho na le khatello e kholo ea masala sebakeng sa welding, le litlamorao tse mpe tsa khatello e setseng.E bonahatsoa feela tlas'a maemo a itseng.Ha khatello ea kelello e setseng e kopana le hydrogen ka har'a weld, e tla khothalletsa ho thatafala ha sebaka se anngoeng ke mocheso, e leng se fellang ka ho hlahisa mapetsong a batang le mapetsong a liehang.

Ha khatello ea maikutlo e sa tsitsang e setseng ho weld kapa khatello e matla ea mojaro ts'ebetsong ea mojaro e kopantsoe le ketso e senyang ea seaplane, e ka baka corrosion ea crack, e leng seo ho thoeng ke khatello ea maikutlo.Khatello ea masala ea welding le ho thatafala ha tšepe ho bakoang ke ho cheselletsa ke lintlha tsa bohlokoa bakeng sa ho phatloha hoa khatello ea maikutlo.

Liphello tsa lipatlisiso li bontša hore phello e ka sehloohong ea ho senyeha le khatello e setseng holim'a lisebelisoa tsa tšepe ke ho etsa hore tšepe e fetohe ho tloha ho corrosion e ts'oanang ho ea ho ea sebakeng sa heno, ke hore, ho pota-pota kapa ho pota-pota.Ha e le hantle, ho phunyeha ha corrosion le intergranular corrosion ea tšepe ho etsahala mecheng ea litaba e nang le litšobotsi tse itseng tsa tšepe eo.

Ka boteng ba khatello ea maikutlo, e fapane ho ea ka sebopeho, mahloriso le mocheso oa mocheso o senyang, hammoho le phapang ea sebopeho, sebopeho, boemo ba bokaholimo, boemo ba khatello ea maikutlo, joalo-joalo ea tšepe ea motheo le sebaka sa welding. , e le hore corrosion Sebopeho sa tšenyo e ka fetoha.

5.Ho nahanoa ka phello e akaretsang ea PWHT

Kalafo ea mocheso ka mor'a weld ha e na molemo ka ho feletseng.Ka kakaretso, phekolo ea mocheso ka mor'a weld e molemo bakeng sa ho imolla khatello ea kelello e setseng, 'me e etsoa feela ha ho na le litlhoko tse thata bakeng sa ho senyeha ha khatello ea kelello.Leha ho le joalo, teko ea matla a ts'ebetso ea mohlala e bonts'a hore kalafo ea mocheso ka mor'a weld ha e ntle bakeng sa ho tiea ha tšepe e kentsoeng le sebaka se amehileng ke mocheso oa weld, 'me ka linako tse ling ho phunyeha ha intergranular ho ka etsahala ka har'a mefuta e mengata ea lijo-thollo tsa mocheso oa weld- sebaka se amehileng.

Ho feta moo, PWHT e itšetlehile ka phokotso ea matla a lintho tse bonahalang mochesong o phahameng ho fihlela phomolo ea khatello ea maikutlo.Ka hona, nakong ea PWHT, mohaho o ka lahleheloa ke ho tiea.Bakeng sa meaho e amohelang PWHT e akaretsang kapa e sa fellang, ho chesehela mocheso o phahameng ho tlameha ho nahanoa pele ho kalafo ea mocheso.bokgoni ba ho tshehetsa.

Ka hona, ha ho nahanoa hore na ho etsoa phekolo ea mocheso ka mor'a weld, melemo le melemo ea phekolo ea mocheso e lokela ho bapisa ka ho feletseng.Ho ea ka pono ea ts'ebetso ea sebopeho, ho na le lehlakore le leng la ho ntlafatsa ts'ebetso, 'me ka lehlakoreng le leng ho fokotsa ts'ebetso.Kahlolo e utloahalang e lokela ho etsoa motheong oa ho hlahlojoa ka botlalo ha likarolo tsena tse peli.

Nako ea poso: Jun-20-2023