Tlhokahalo ea tšepe sechabeng sa mehleng ea kajeno e ntse e eketseha.Bophelong ba letsatsi le letsatsi, lintho tse ngata li entsoe ka tšepe, 'me litšepe tse ngata li ke ke tsa lahleloa ka nako e le' ngoe.Ka hona, hoa hlokahala ho sebelisa welding ea motlakase bakeng sa welding.Karolo ea electrode ts'ebetsong ea welding ea motlakase ke ea bohlokoa haholo.

Molamu oa welding o matlafatsoa mme o qhibiliha ka mocheso o phahameng nakong ea welding ea arc, 'me o tlatsa manonyeletso a sesebelisoa sa welding.Hangata, electrode e lumellanang e khethoa ho ea ka thepa ea workpiece ea welding.Molamu oa welding o ka sebelisoa bakeng sa ho tjheseletsa mofuta o tšoanang oa tšepe kapa oa ho tjheseletsa lipakeng tsa litšepe tse fapaneng.

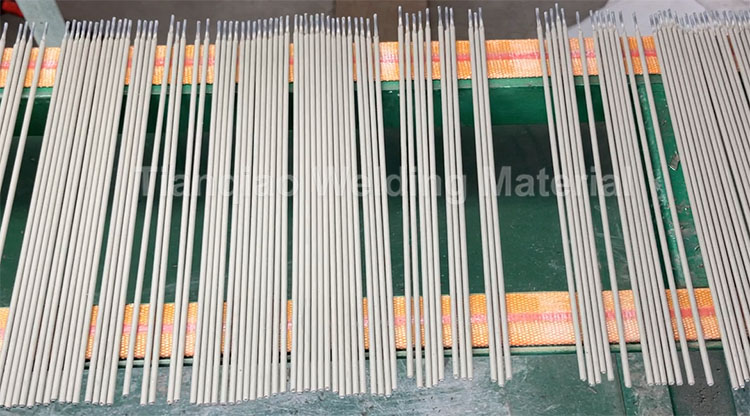

Sebopeho sa Welding Electrode

Mokotla oa tšepe o ka hare oa molamu oa welding le seaparo sa ka ntle se entsoe.Mokotla oa welding ke terata ea tšepe e nang le bophara bo itseng le bolelele.Mosebetsi o ka sehloohong oa mokokotlo oa welding ke ho tsamaisa hona joale ho futhumatsa le ho qhibiliha, le ho tlatsa le ho hokahanya workpiece.

Lisebelisoa tsa mantlha tse sebelisetsoang ho tjheseletsa li ka aroloa ka tšepe ea carbon, alloy steel le tšepe e sa hloekang.Leha ho le joalo, e le ho finyella litlhoko tsa ho cheselletsa, ho na le litlhoko tse khethehileng bakeng sa lisebelisoa le lisebelisoa tsa tšepe tsa mantlha, 'me ho na le melao e thata ka litaba tsa likarolo tse ling tsa tšepe.Hobane sebopeho sa tšepe sa mantlha sa welding se tla ama ka kotloloho boleng ba weld.

Ho tla ba le lera la ho roala ka ntle ho electrode, e bitsoang seaparo sa flux.Flux coat e phetha karolo ea bohlokoa.Haeba motlakase tjheseletsa konokono e sebelisoa ho ka ho toba tjheseletsa workpiece, moea le lintho tse ling li tla kena ka tšepe e qhibilihisitsoeng ea motheo tjheseletsa motlakase, 'me karabelo ea lik'hemik'hale tla etsahala ka tšepe e qhibilihisitsoeng ho etsa hore ka ho toba tjheseletsa.Mathata a boleng a kang li-pores le mapetsong a tla ama matla a ho cheselletsa.Seaparo sa Flux se nang le likarolo tse khethehileng se tla senyeha ebe se qhibiliha ho ba khase le slag ka mocheso o phahameng, o ka thibelang moea ho kena le ho ntlafatsa boleng ba welding.

Metsoako ea seaparo sa flux e kenyelletsa: hydrochloric acid, fluoride, carbonate, oxide, organic matter, alloy ea tšepe le phofo e meng ea lik'hemik'hale, joalo-joalo, e kopantsoeng ho latela tekanyo e itseng ea foromo.Sebopeho sa ho roala ha mefuta e fapaneng ea li-electrode le tsona li fapane.

Ho na le mefuta e meraro e tloaelehileng, e leng moemeli oa slag, agent e hlahisang khase, le deoxidizer.

Setsi sa slag ke motsoako o ka sireletsang tšepe e qhibilihisitsoeng ho tloha moeeng ha elektrode e qhibiliha, kahoo e ntlafatsa boleng ba welding.

Setsi se hlahisang khase haholo-holo se entsoe ka phofo ea starch le lehong le lintho tse ling, tse nang le tekanyo e itseng ea ho fokotseha.

Deoxidizer e entsoe ka ferro-titanium le ferromanganese.Ka kakaretso, lintho tse joalo li ka ntlafatsa ho hanyetsa ha tšepe le ho hanyetsa kutu ea tšepe.

Ho phaella moo, ho na le mefuta e meng ea ho roala holim'a electrode, 'me sebopeho le karolelano ea mofuta o mong le o mong li tla fapana.

Mokhoa oa ho hlahisa li-electrode tsa welding

Mokhoa oa ho etsa molamu oa ho tjheseletsa ke ho etsa motheo oa ho tjheseletsa le ho lokisa seaparo ho latela litlhoko tsa moralo oa molamu oa ho tjheseletsa, le ho sebelisa ho roala ka mokhoa o ts'oanang holim'a mokokotlo oa welding ho etsa hore o finyelle litlhoko tsa moralo oa molamu o tšoanelehang.

Ntlha ea pele, tšepe e kolobisitsoeng e ntšoa ho tloha ho coiler, mafome holim'a tšepe ea tšepe e tlosoa ka mochine, ebe e otloloha.Mochine o khaola tšepe ea tšepe ho fihlela bolelele ba electrode.

Ka mor'a moo, ho lokela ho lokisoa ho roala holim'a electrode.Lisebelisoa tse sa tšoaneng tse entsoeng ka ho roala li siefa ho tlosa litšila, ebe li tšeloa ka mochine ho ea ka tekanyo, 'me sekontiri se eketsoa ka nako e le' ngoe.Lisebelisoa tsohle tse tala li kopantsoe ka ho feletseng ke ho ferekanngoa ha mochine.

Beha phofo e tsoakiloeng ka har'a hlobo 'me ue hatelle ka cylindrical cylinder e nang le lesoba le chitja bohareng.

Kenya libarele tse ngata tse hatelitsoeng mochining, beha li-cores tsa welding ka makhethe ka har'a boema-kepe ba phepelo ea mochini, li-cores tsa welding li kena mochining ho tloha boema-kepeng ba phepelo ea mochini ka ho latellana, 'me li-cores tsa wedling li feta bohareng ba moqomo ka lebaka la extrusion.Mochini o ala phofo ka mokhoa o ts'oanang holim'a mokokotlo o fetang hore e be seaparo.

Nakong ea ts'ebetso ea ho roala ha molamu oa welding, mokokotlo oohle oa welding o koahetsoe ka lera la ho roala.E le ho etsa hore electrode e be bonolo ho koala le ho tsamaisa motlakase, hlooho le mohatla oa electrode li hloka ho belisoa ho tloha holim'a seaparo ho pepesa motheo oa tjheseletsa.

Ka mor'a hore ho sebelisoe ho roala, hlooho ea ho sila le molamu oa ho cheselletsa ka mor'a ho sila mohatla o tla hlophisoa ka mokhoa o ts'oanang holim'a foreimi ea tšepe ebe o romeloa ka ontong bakeng sa ho omisa.

E le hore u khone ho khetholla habonolo litlhaloso le mehlala ea electrode, ho hlokahala hore u hatise ka electrode.Ha molamu oa welding o tsamaea holim'a lebanta la conveyor, electrode e 'ngoe le e' ngoe e hatisoa ke rolara ea khatiso ea rabara holim'a lebanta la conveyor.

Ka mor'a hore mohlala oa welding o hatisoe, molamu oa welding o ka kenngoa le ho rekisoa ka mor'a ho feta tlhahlobo.

Li-electrode tsa welding tsa brand Tianqiao li na le ts'ebetso e ntle haholo, boleng bo tsitsitseng, ho bopa ka mokhoa o motle, le ho tlosoa ha slag hantle, bokhoni bo botle ba ho hanela mafome, Stomata le ho phatloha, litlhaku tse ntle le tse tsitsitseng tse behiloeng tsa mechini ea tšepe.Lisebelisuoa tsa welding tsa mofuta oa Tianqiao li kopana le kamohelo e mofuthu ea bareki ka lebaka la boleng bo holimo, ts'ebetso e ikhethang le theko ea tlholisano.tlanya monaho sheba haholoanyane ka lihlahisoa tsa rona

Nako ea poso: Sep-03-2021