LIKOPO:

E sebelisoa bakeng sa ho cheselletsa mofuta o tšoanang oa tšepe e sa jeleng mocheso e sebetsang tlas'a maemo a mocheso o phahameng, hape bakeng sa ho cheselletsa litšepe tse thata tsa chrome (joalo ka Cr5Mo, Cr9Mo, Cr13, Cr28 le tse ling) le litšepe tse sa tšoaneng.

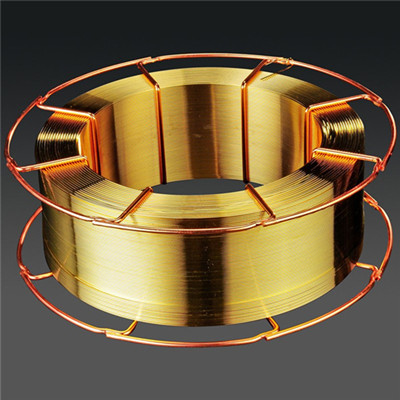

LITŠOANTŠISO:

E310-16ke Cr26Ni21 elektrode ea tšepe e sa hloekang bakeng sa lisebelisoa tsa khatello ea letlalo la rutile.Ka bobeli AC le DC li ka sebelisoa bakeng sa ho tjheseletsa maemo ohle.Electrode ena e na le ts'ebetso e ntle ea ts'ebetso ea welding, 'me tšepe e kentsoeng e na le khanyetso e ntle ea oxidation tlasa 900-1100 ℃ maemo a mocheso o phahameng.

HLOKOMELA:

1. Pele ho welding, electrode e tla behoa ka 300-350 ℃ bakeng sa hora e le 'ngoe ebe e sebelisoa ha ho hlokahala.

2. Tlosa mafome, mafura, mongobo le litšila tse ling pele u cheselletsa.

3. Motlakase oa DC o buelloa, hobane botebo ba welding ea hona joale e batla e sa teba, hona joale ha ea lokela ho ba khōlō haholo, e le ho qoba bofubelu le ho phatloha ha letlalo.

4. Fokotsa mocheso oa mocheso ka hohle kamoo ho ka khonehang, 'me amplitude ea swing ea electrode ha ea lokela ho ba khōlō haholo.

5. Preheat 'me u boloke mocheso pakeng tsa likanale tse ka tlase ho 150 ℃.

MAEMO A CHESO:

PA, PB, PC, PD, PE, PF

MOSEBETSI OA K'hemik'hale OA TŠEPE TSOHLE: (Wt. %)

| Lintho | C | Mn | Si | S | P | Ni | Cr | Mo | Cu |

| Litlhoko | 0.08-0.20 | 25.0-28.0 | ≤0.75 | ≤0.03 | ≤0.03 | 20.0-22.5 | 25.0-28.0 | ≤0.75 | ≤0.75 |

| Liphetho tse Tloaelehileng | 0.11 | 0.89 | 0.69 | 0.010 | 0.025 | 20.86 | 26.21 | 0.05 | 0.08 |

LITLHAKISO TSA MOSEBETSI OA TSOHLE TSA METAL TSA WELD:

| Lintho | Rm/MPa | A/% |

| Litlhoko | ≥550 | ≥25 |

| Liphetho tse Tloaelehileng | 605 | 38 |

TSELA E TLOAELEHANG EA TSEBETSI: (AC kapa DC+)

| Diameter (mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 |

| Hona joale (A) | 25-50 | 50-80 | 80-110 | 110-160 | 160-200 |

PHEKOA:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet.21MT -26MT ka 1X20″ FCL.

Tlhahlobo ea boima ba li-welds:

Bakeng sa li-welds tseo khatello ea tsona ea ho sebetsa e ka tlase ho 0.3MPa, parafine e ka sebelisoa bakeng sa tlhahlobo ea tiiso.Teko e tla etsoa ho latela lipehelo tse latelang: 5.1.1.1 Mocheso nakong ea tlhahlobo ha oa lokela ho ba ka tlase ho 5 ° C.

Apara bokantle ba sengoathoana sa teko ka phofo e tšoeu, 'me u tlose parafine e lekaneng ka hare.Ka kakaretso, ka mor'a metsotso e 15 ho isa ho e 30, haeba ho se na matheba a matšo a oli holim'a phofo e tšoeu, weld e nkoa e se na sekoli.Ho e-na le hoo, hoa hlokahala ho tlosa sebaka se nang le sekoli le ho etsa soldering hape, ebe o etsa tlhahlobo.

Ha o sebelisa khatello ea hydraulic ho leka ho tiea ha setshelo, e lokela ho etsoa ho latela melaoana e latelang:

Khatello ea teko e lokela ho nyoloha butle ho feta makhetlo a 1.5 khatello ea ho sebetsa.

Ha weldment e fihla khatellong ea teko, khatello e tlameha ho bolokoa metsotso e 5.Haeba ho na le ho lutla kapa mongobo ho weld, karolo e nang le bokooa e tlameha ho tšoauoa, e tlosoe, e tsoetsoe hape, ebe e hlahlojoa.

Nakong ea teko ea khatello ea workpiece, ha e lumelloe ho lokisa weld;'me ha workpiece e tlas'a khatello ea teko, ha e lumelloe ho otla weld.

Teko ea ts'ebetso ea mochini oa li-welds:

Sampling ea liteko e tla nkuoa lisampoleng tse nang le lisebelisoa tse tšoanang le likarolo tsa ts'ebetso ea likarolo tse cheselitsoeng.

Mofuta le boholo ba tlhahlobo ea ts'ebetso li lokela ho lumellana le litekanyetso tse loketseng tsa GB/T 2649 ~ 2653.

electrode, electrode, welding,tjheseletsa electrodeli-electrode tsa welding,molamu oa ho cheselletsa,molamu oa ho cheselletsas, theko ea electrode, electrode welding, welding rod factory price, welding stick, stick welding, welding stick, china welding rods, stick electrode, welding consumables, welding consumable, China electrode, welding electrode China, carbon steel welding electrode, carbon steel li-electrode tsa tjheseletsa,tjheseletsa electrode feme,Sechaena feme ea China welding electrode, China welding rod, welding rod price, welding rod, the welding welding, wholesale welding products,global welding, arc welding, phepelo ea lintho tse bonahalang, arc welding, tšepe welding, easy arc welding electrode, arc welding electrode,arc welding electrode,vertical welding electrode,price of welding electrode, cheap welding electrode,acid welding electrode,alkaline welding electrode,cellulosic welding electrode,china welding electrode,factory electrode, small size welding electrode, welding material,welding rod material,welding electrode holder,nickel welding rod,j38.12 e6013,welding rods e7018-1,welding stick electrode,welding rod 6010,welding electrode e6010,welding rod e7018,welding electrode e6011 ,welding rods 7 electrodes e70 li-electrode tsa welding e7018, welding rod 6013, welding rods 6013, welding electrode 6013, welding electrode e6013,6010 welding rod, 6010 welding electrode, 6011 welding rods, 6011 welding electrode, 6013 welding rod3011 li-electrode,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrode, welding electrode e7016,e6010 welding rod,e6011 welding rod,e6011 welding rod,18 welding rod,18 rod. e6013 welding electrode,e7018 welding electrode,e7018 welding electrode,J421 welding electrode,J422 welding electrode,wholesale e6010,wholesale e6013,wholesale e6013,wholesale e7018 electrodebelding2, electrode belding2 , molamu oa tšepe o sa hloekang, electrode ea tšepe e sa hloekang, SS welding electrode, welding rods e307, welding electrode e312,309l welding rod,316 welding electrode, e316l 16 welding electrode, cast iron welding electrode, aws Eni-Ci,aws Enife-Ci,surfacing tjheseletsa, molamu o shebileng ka thata, ho tjheseletsa ka thata hodima sefahleho, ho tjheseletsa ka thata, ho tjheseletsa, ho tjheseletsa, ho tjheseletsa, ho tjheseletsa, bohler welding, lco welding, miller welding, atlantic welding, welding, flux powder, welding flux, welding powder, welding electrode flux material, welding electrode flux, welding electrode material,tungsten electrode,tungsten electrode, welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,electric are welding,electric arc welding,arc welding rods,carbon arc welding , E6013 rod e sebelisa, mefuta ea li-electrode tse tjheseletsang, flux core welding, mefuta ea li-electrode ho tjheseletsa, phepelo ea welding, tšepe ea ho tjheseletsa, tšepe e sirelelitsoeng, welding ea tšepe e sirelelitsoeng, aluminium welding, welding aluminium e nang le mig, aluminium mig welding, welding pipe, mefuta ea li-welding rod, mefuta eohle ea li-welding rod, li-welding rod amperage, welding rod amperage, welding rod electrode, welding electrode classification, welding electrode classification, welding electrode aluminium, welding electrode diameter, welding electrode diameter, welding steel, E6011 welding rod e sebelisa, boholo ba lithupa tsa welding, theko ea li-welding rods, welding electrode size, aws e6013, aws e7018, aws er70s-6, terata ea tšepe e sa hloekang, terata ea tšepe e sa hloekang ea mig, terata ea welding ea tig, thupa ea welding e tlase, 6011 rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,lihlahiswa tsa welding,welding tech, feme

E fetileng: Stainless Steel Welding Electrode AWS E309L-16(A062) E 'ngoe: Stainless Steel Welding Electrode AWS E312-16