Ha ho na phapang lipakeng tsa ts'ebetso lipakeng tsa welding e felletseng ea argon arc le welding ea argon arc.Full argon arc welding e loketse liphaephe tse tšesaane tse nang le bophara bo nyane (ka kakaretso DN60 le ka tlase, botenya ba lebota 4mm), sepheo ke ho netefatsa boleng ba motso oa weld le ponahalo.

Ha bophara ba phala bo le boholo 'me botenya ba lebota bo le botenya, welding ea argon arc e lokela ho sebelisoa e le motheo le mokhoa oa matsoho ho koahela bokaholimo.Sepheo sa ho tjheseletsa ka letsoho ke ho netefatsa boleng ba ponahalo ea bophara ba pipe e kholo le ho kenya letsoho ka letsoho, 'me katleho ea mosebetsi e phahame ho feta ea argon arc welding.e tlase hofeta arc welding.

The argon arc welding bottom welding process e sebelisoa ho tjheseletsa mabota a metsi a boiler, li-superheaters, economizers, joalo-joalo. Boleng ba manonyeletso bo ntle haholo, 'me limaraka tsa weld li ka holimo ho Sehlopha sa II ka mor'a tlhahlobo ea radiographic.

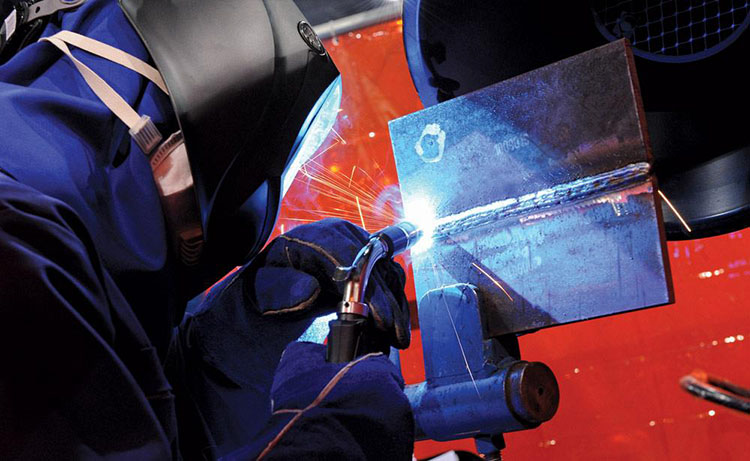

Melemo ea argon arc welding

(1) boleng bo botle

Hafeela terata e loketseng ea ho tjheseletsa e khethiloe, litekanyetso tsa ts'ebetso ea welding le tšireletso e ntle ea khase li khethoa, motso o ka fumana ho kenella hantle, 'me ho kenella ho tšoana,' me bokaholimo bo boreleli ebile bo le makhethe.Ha ho na litšitiso tse kang li-weld bumps, ho kenella ho sa phethoang, ho tepella maikutlo, li-pores le li-slag inclusions tse bonolo ho etsahala nakong ea li-arc welding ka li-electrode tse akaretsang.

(2) Ho sebetsa hantle haholo

Karolong ea pele ea tjheseletsa ea liphaephe, ho tjheseletsa ha argon arc ka letsoho ke tjheseletso e tsoelang pele.The electrode arc welding is broken arc welding, kahoo manual argon arc welding e ka eketsa bokhoni ka makhetlo a 2 ho isa ho a 4.Kaha argon arc welding ha e hlahise welding slag, ha ho hlokahale ho hloekisa slag le ho lokisa sefaha sa weld, 'me lebelo le tla eketseha ka potlako.Karolong ea bobeli ea sekoaelo sa arc welding, karolo e ka tlase e boreleli le e makhethe ea arc welding e molemo haholo ho sekoaelo sa sekoaelo sa arc, se ka netefatsang fusion e ntle lipakeng tsa lera, haholo ts'ebetsong ea liphaephe tse nyane tsa bophara, ts'ebetso e ntle e feta. bohlokoa.

(3) Ho bonolo ho e tseba

Ho tjheseletsa ha motso weld ya manual arc welding ho tlameha ho etswa ke batho ba nang le boiphihlelo le ba nang le boiphihlelo bo boholo.Manual argon arc welding e sebelisetsoa ho tšehetsa, 'me basebetsi bao ka kakaretso ba etsang mosebetsi oa ho cheseletsa ba ka khona ho e tseba ka mor'a nako e khuts'oane ea boikoetliso.

(4) Phetoho e nyane

Sebaka se amehileng ke mocheso se nyane haholo nakong ea welding ea argon arc, kahoo deformation ea lenonyeletso le nang le welded e nyane mme khatello e setseng le eona e nyane.

Kenyelletso ea ts'ebetso

(1) Mohlala oa ho cheselletsa

The economizer, evaporator tube bundle, lerako la metsi le mocheso o tlaase oa mocheso oa mocheso o tlaase o entsoe ka tšepe ea No. 20, 'me mocheso o phahameng oa mocheso oa mocheso ke 12Cr1MoV.

(2) Ho itokisa pele ho tjheseletsa

Pele ho tjheseletsa, molomo oa phala o lokela ho koaheloa ka likhato tse 30°, 'me' mala oa tšepe o lokela ho belisoa ka hare ho 15mm ka hare le ka ntle ho qetellong ea pipe.Lekhalo pakeng tsa liphaephe tsa liphaephe ke 1 ~ 3mm.Ha lekhalo la 'nete le le leholo haholo, ho hlokahala hore u phahamise lera la phetoho ka lehlakoreng la pipe groove pele.Theha lisebelisoa tsa nakoana tsa bolulo ba moea 'me u laole lebelo la moea ka thata sebakeng sa ts'ebetso ea tjheseletsa, hobane lebelo la moea le feta mefuta e itseng,' me masoba a moea a hlahisoa habonolo.

(3) Ts'ebetso

Sebelisa mochini oa welding oa tungsten argon arc welding, mochini oa welding ka boeona o na le sesebelisoa sa ho khantša arc se nang le maqhubu a phahameng, 'me ho ka sebelisoa khanya e phahameng ea arc.Ho tima li-arc ho fapane le li-electrode arc welding.Haeba arc e tima ka potlako, mapetsong a arc crater ho bonolo ho etsahala.Ka hona, nakong ea ts'ebetso, letamo le qhibilihisitsoeng le lokela ho isoa moeling kapa tšepe e teteaneng, ebe butle-butle fokotsa letamo le qhibilihisitsoeng ho tima arc butle-butle, 'me qetellong le koale arc.Khase e sireletsang.

Bakeng sa lipeipi tsa tšepe tsa No. 20 tse nang le lerako la 3 ~ 4mm, thepa ea ho tlatsa e ka ba TIGJ50 (bakeng sa 12Cr1MoV, 08CrMoV e ka sebelisoa), bophara ba molamu oa tungsten ke 2mm, hona joale welding ke 75 ~ 100A, arc motlakase ke 12 ~ 14V, 'me lebelo la ho phalla ha khase e sireletsang ke 8 ~ 10L / min, mofuta oa phepelo ea motlakase ke khokahanyo e ntle ea DC.

Lebaka leo ka lona argon arc welding e ka sebelisoang haholo ke ka lebaka la melemo e latelang.

1. Tšireletso ea Argon e ka arola liphello tse mpe tsa oksijene, naetrojene, hydrogen, joalo-joalo moeeng holim'a arc le letamo le entsoeng ka ho qhibilihisoa, ho fokotsa tahlehelo e tukang ea likarolo tsa motsoako, le ho fumana manonyeletso a teteaneng, a se nang spatter, a boleng bo phahameng;

2. The arc combustion ea argon arc welding e tsitsitse, mocheso o tsepamisitsoe, mocheso oa kholomo ea arc o phahame, ts'ebetso ea tlhahiso ea welding e phahame, sebaka se amehileng ke mocheso se moqotetsane, 'me khatello ea maikutlo, deformation le ho phatloha ha li-welded likarolo tse nyenyane;

3. Argon arc welding e bulehile arc welding, e leng bonolo bakeng sa ts'ebetso le ho shebella;

4. Tahlehelo ea li-electrode e nyane, bolelele ba arc bo bonolo ho bo boloka, 'me ha ho na flux kapa lera la ho roala nakong ea welding, kahoo ho bonolo ho lemoha mochine le ho iketsetsa;

5. Argon arc welding ka tjheseletsa hoo e ka bang litšepe tsohle, haholo-holo tse ling tse refractory le litšepe habonolo oxidized, tse kang magnesium, titanium, molybdenum, zirconium, aluminium, joalo-joalo le metsoako ea bona;

6. Ha e felle feela ke boemo ba weldment, 'me e ka chesetsoa maemong ohle.

Litšitiso tse kholo:

1. Ka lebaka la sebaka se seholo se amehileng ke mocheso oa argon arc welding, workpiece e atisa ho baka deformation, boima bo phahameng, blisters, annealing sebakeng seo, ho phunyeha, li-pinholes, ho roala, li-scratches, undercuts, kapa matla a sa lekaneng a tlamahano le khatello ea kelello ea ka hare ka mor'a ho lokisoa.mefokolo joalo ka tshenyo.Haholo-holo ts'ebetsong ea ho lokisa liphoso tse nyenyane tsa lichelete tsa lichelete, e hlahella holimo.Sebakeng sa ho lokisa mefokolo ea li-castings tse nepahetseng, ho ka sebelisoa mechini e batang ea welding sebakeng sa welding ea argon arc.Ka lebaka la ho lokolloa ha mocheso o monyenyane oa mechine e batang ea ho tjheseletsa, mefokolo ea argon arc welding e hlōloa hamolemo, 'me mathata a ho lokisa li-castings tse nepahetseng a etsoa bakeng sa.

2. Argon arc welding e kotsi haholo 'meleng oa motho ho feta electrode arc welding.Boima ba hona joale ba argon arc welding bo phahame, 'me khanya e hlahisoang e batla e le matla.Mahlaseli a ultraviolet a hlahisoang ke arc ea eona a batla a le a tloaelehileng a li-electrode arc welding.Ka makhetlo a 5 ho isa ho a 30, 'me mahlaseli a infrared a ka ba makhetlo a 1 ho isa ho a 1.5 ho feta a li-electrode arc welding.Likahare tsa ozone tse hlahisoang nakong ea welding li batla li phahame.Ka hona, leka ho khetha sebaka se nang le potoloho e ntle ea moea bakeng sa kaho, ho seng joalo e tla baka kotsi e kholo 'meleng.

3. Bakeng sa litšepe tse nang le ntlha e tlaase ea ho qhibiliha le ho fetoha mouoane habonolo (joaloka loto, thini, zinki), ho thatafala le ho feta.

Nako ea poso: Aug-16-2023