Nakong ea ho kopanya tjheseletsa, tlas'a ketso ea mohloli oa mocheso oa tjheseletsa, karolo ea tšepe ea mokelikeli e nang le sebōpeho se itseng sa thutatekanyo e entsoeng ka tjheseletsa ka tšepe ea elektrode e qhibilihisitsoeng le tšepe e sa fellang e qhibilihisitsoeng ke letamo le qhibilihisitsoeng.Ka mor'a ho pholile, e fetoha weld, kahoo mocheso oa letamo le qhibilihisitsoeng o ama ka ho toba boleng ba ho cheselletsa.

Haeba mocheso oa letamo le qhibilihisitsoeng o phahame, letamo le qhibilihisitsoeng le le leholo, 'me tšepe e qhibilihisitsoeng e na le metsi a matle, sebaka sa fusion se bonolo ho fuse;empa ha mocheso o le holimo haholo, tšepe e qhibilihisitsoeng e rotha habonolo, 'me karolo e ka morao ea tjheseletsa e nang le lehlakore le le leng le ho etsoa ka mahlakoreng a mabeli ho bonolo ho chesoa, ho etsa makukuno le sebōpeho.Ho thata ho laola, 'me polasetiki ea motsoako e fokotsehile,' me motsoako o bonolo ho senya;ha mocheso oa letamo le entsoeng ka ho qhibilihisoa o le tlaase, letamo le entsoeng ka ho qhibilihisoa le le lenyenyane, tšepe e qhibilihisitsoeng e le lefifi haholoanyane, ’me metsi a fokola.Ho bonolo ho hlahisa mefokolo e kang ho kenella ho sa fellang, ho hloka fusion, le ho kenyelletsa slag.

Ka hona, ho laola ka katleho mocheso oa letamo le qhibilihisitsoeng ke habohlokoa haholo ho etsa bonnete ba hore phello ea welding le boleng ba sehlahisoa se felileng.

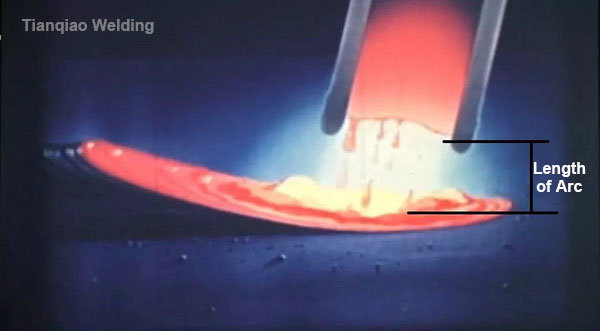

Setšoantšo sa 1 Tianqiao welding

Mocheso oa letamo le entsoeng ka ho qhibilihisoa o amana haufi-ufi le hona joale oa welding, bophara ba electrode, mokhoa oa ho tsamaisa, angle ea electrode, le nako ea ho chesa arc.Mehato e latelang e nkoa ho laola mocheso oa letamo le qhibilihisitsoeng ho latela lintlha tse amehang.

1. Hona joale welding le bophara ba electrode

Likarolo tsena tse peli ke lintlha tsa bohlokoa bakeng sa ho cheselletsa, 'me tse peli le tsona li na le tlamo e ke keng ea arohana.Nakong ea ho tjheseletsa ha fusion, hona joale ho phallang morao ka har'a weldment ho bitsoa welding current.Bophara ba electrode bo bolela boholo ba karolo ea sefapano sa molamu oa tšepe oa filler.Ka mantsoe a bonolo, hore na molamu oa welding o ka qhibiliha hantle o khethoa ke ho fetisoa ha hona joale.

Haeba hona joale e le nyenyane haholo, ho thata ho qala arc, electrode e bonolo ho khomarela weldment, sekala sa litlhapi se teteaneng, 'me mahlakoreng a mabeli ha a kopane;haeba hona joale e le khōlō haholo, ho phatloha le mosi nakong ea welding e tla ba khōlō, electrode e tla ba khubelu, 'me bokaholimo ba letamo le qhibilihisitsoeng le tla khanya haholo.Ho bonolo ho chesoa le ho fokotsa;ha hona joale ho loketse, ho bonolo ho hotetsa 'me arc e tsitsitse, ho phatloha ho honyenyane, molumo o tšoanang oa ho roala o ka utluoa, mahlakoreng a mabeli a seam sa welding a fetela ka mokhoa o thellang ho thepa ea motheo, sekala sa tlhapi se holim'a metsi se matla haholo. tšesaane, le tjheseletsa slag bonolo Knock tsoa.Mabapi le ts'ebeliso ea eona, ho na le likamano tse rarahaneng.

1.1 Khetha tjheseletsa hona joale le eleketrode bophara ho ea ka sebaka boemo ba weld

Libakeng tse otlolohileng, tse tšekaletseng le tse otlolohileng, ea hona joale e nyane ka tsela e tšoanang ho feta ea tjheseletsa e bataletseng, 'me ea hona joale hangata e lokela ho ba nyane ka 10% ho feta ea tjheseletsa e bataletseng.

Ka mokhoa o ts'oanang, maemong a emeng, a tšekaletseng, le a otlolohileng, bophara ba eleketrode hangata bo nyane ho feta ba welding e bataletseng.Ka mohlala, ka tjheseletsa e bataletseng ea poleiti e sephara e kholo ho feta 12mm, hangata ho sebelisoa electrode ea 5.0mm., 'Me ho na le hoo e ka bang ha ho na eleketrode e nang le bophara ba 5.0mm maemong a holimo, a holimo le a holimo.

1.2 The tjheseletsa hona joale le eleketrode bophara ba khetha ho ea ka tjheseletsa boemo ba weld.

Ka mohlala, bakeng sa 12mm flat plate butt joints, 3.2mmLi-electrode tsa TianqiaoHangata li sebelisoa bakeng sa lera le ka tlase la tjheseletsa e bataletseng, 'me hona joale tjheseletsa ke 90-110A, le 4.0mm.Li-electrode tsa Tianqiaoe ka sebelisoa bakeng sa ho tlatsa le ho koahela lera, 'me hona joale welding ke 160-175A.

Ka hona, khetho e utloahalang ea hona joale ea tjheseletsa le bophara ba electrode e ka laola habonolo mocheso oa letamo le qhibilihisitsoeng, e leng motheo oa sebopeho se setle sa weld.Haeba hona joale welding e nyane haholo, mocheso oa letamo la weld o tlase haholo, o etsa hore arc e se ke ea tsitsa, 'me workpiece e ka' na ea se ke ea kenngoa.Haeba hona joale tjheseletsa e phahameng haholo 'me mocheso oa letamo ho qhibilihisoa o phahame haholo, e tla etsa hore ho be le ho phatloha ho hoholo le ho phalla ha tšepe e qhibilihisitsoeng, esita le ho chesa ka har'a workpiece ho etsa bead ea ho cheselletsa.

Kamano pakeng tsa tjheseletsa hona joale le bophara ba eleketrode e thathamisitsoe ka tlaase mona.U ka etsa khetho e nepahetseng ho latela boiphihlelo kapa litloaelo tsa hau.Ha ho hlokahale hore u tsebe li-parameter tse tšoanang le tse ling, ha feela u ikutloa eka li loketse 'me u netefatse hore ho na le sebopeho se setle sa weld.

2. Lipalangoang tsa molamu oa welding

Themolamu oa ho cheselletsae feptjoa ka nqa ya letamo le qhibidihang ho bapa le axis.Ka mor'a hore molamu oa welding o qhibilihe, bolelele ba arc bo ka tsoela pele ho hlokomeloa.Ka hona, lebelo la molamu oa welding ka tataiso ea letamo le qhibilihisitsoeng le hlokahala hore le lekane le lebelo la ho qhibiliha ha molamu oa welding.

Haeba lebelo la ho fepa la electrode le le tlaase ho feta lebelo la ho qhibiliha ha electrode, bolelele ba arc bo tla eketseha butle-butle, bo fella ka ho sitisoa ha arc;haeba lebelo la ho fepa la electrode le potlakile haholo, bolelele ba arc bo tla khutsufatsoa ka potlako, 'me qetellong ea electrode e tla ba khutšoanyane-circuited ha e kopana le weldment.Tima arc.

Setšoantšo sa 2 Tianqiao welding

3. Angle ea ho pepa le boemo ba ho fepa

Nakong ea ho tjheseletsa, angle ea eleketrode e lokela ho fetoha le boemo ba tjheseletsa, 'me kamehla u boloke mocheso oa letamo le qhibilihisitsoeng ka mahlakoreng ka bobeli a bohale bo hlabang bo loketseng.Haeba mocheso o phahame haholo, o tla baka ho chesa, 'me haeba o le tlase haholo, o tla etsa hore ho be le ts'ebetso e sa lekaneng ea ho kenella le ho kopanya.Ha angle pakeng tsa eleketrode le tataiso ea tjheseletsa ke likhato tse 90, arc e tsepamisitsoe 'me mocheso oa letamo le qhibilihisitsoeng o phahame;

Haeba angle e fetoha e nyane, arc e tla qhalakanngoa mme mocheso oa letamo le qhibilihisitsoeng o tla ba tlase.Ka mohlala, haeba lera e ka tlaase ea 12mm a bataletseng tjheseletsa tiiso, haeba tjheseletsa molamu angle ke likhato 50-70, mocheso oa letamo le qhibilihisitsoeng tla theoleloa ka nako ena, 'me ketsahalo ea ho tjheseletsa sefaha kapa tsoha ka morao lehlakoreng. e qojoa.Bakeng sa mohlala o mong, ka mor'a ho fetola molamu oa ho tjheseletsa botlaaseng ba 12mm poleiti e otlolohileng ea ho tjheseletsa seal, re sebelisa 90-95 degree rod angle ha re tsamaisa molamu oa ho tjheseletsa, e le hore mocheso oa letamo le qhibilihisitsoeng o ka eketseha ka potlako. lesoba le qhibilihisitsoeng le ka buloa hantle, 'me bokaholimo bo ka morao bo etsoa bo bataletse, bo ka laoloang ka katleho.Ketsahalo ea hore ntlha e kopanetsoeng e concave.

Haeba sebaka sa phepelo ea elektrode se sa lekana, se tla baka ho kenella ho sa lekaneng kapa ho koala li-groove.Hobane arc e batla e qhalakantsoeng ka nako ena, mocheso o qhibilihang oa moeli o sa hlakang oa thepa ea motheo ha oa lekana, o fella ka ho kopanngoa ha thepa ea motheo ka tlaase;haeba u batla ho qhibilihisa tšepe ka botlalo, u tlameha ho eketsa nako ea ho qhibiliha.Welding, multi-layer superposition ea letamo le entsoeng ka ho qhibilihisoa ho tla hlahisa ketsahalo ea ho kenyelletsa slag.

Mokhoa o nepahetseng ke ho holisa molamu oa tjheseletsa ka har'a groove e boreleli ka lehlakoreng la likhato tse 75, ho hokahanya lisebelisoa tsa motheo tsa groove ho qhibiliha le ho tsukutleha ka mahlakoreng ka bobeli, ketso e 'ngoe le e' ngoe e nka metsotsoana e le 1, ho fihlela joale letamo la pele le qhibilihisitsoeng le thehoa. ebe ho kena e latelang Popeho ya letamo le qhibidihileng.Ka nako ena, nako ea ho qhibiliha ea letamo le leng le le leng le qhibilihisitsoeng e khutšoanyane 'me boima bo bobebe,' me ha boa lokela ho baka ho oa, 'me leqhubu la welding le ke ke la theha.The groove e sa tebang e boetse e thusa ho cheselletsa holim'a sekoahelo.

Letamo la ho qetela le entsoeng ka ho qhibilihisoa le koahela 2/3 ea e fetileng.Letamo le leng le le leng le qhibilihisitsoeng le tšesaane, 'me la ho qetela le na le phello ea ho qhibiliha ka mor'a mocheso ho le fetileng, ho netefatsa hore khase e ka letamong la ho qhibiliha e na le nako e lekaneng ea ho phalla le ho thibela hore e se ke ea hlahisoa.Stomata.

Setšoantšo sa 3 Tianqiao welding

4. Nako ea ho chesa arc

Ka mokhoa oa ho ruta oa tjheseletsa e tsitsitseng le e otlolohileng ea liphaephe tse 57 × 3.5, mokhoa oa ho senya arc o sebelisoa bakeng sa welding.Ha u qala welding, mocheso oa tšepe ea motheo o tlaase.Haeba molamu oa welding o sa behoe moeling oa groove, tšepe e qhibilihisitsoeng e tla khutlela morao kapele ebe e hlahisa li-undercuts.Sebopeho sa weld se tla boela se be se phahameng le se moqotetsane, se ke keng sa finyella phello ea boreleli bo feteletseng, 'me se bonolo Sebaka se hlahisoang ha se kopane.

Ho hlahloba ho tloha sebōpeho sa letamo le qhibilihisitsoeng, haeba le le ka sebōpeho sa lerotholi le oelang, sebopeho se cheselitsoeng ha se hantle, 'me ho ka etsahala hore ho be le bead ea welding.Ka hona, ntlha ea tjheseletsa e lokela ho futhumatswa ka botlalo ho tloha ho welding e holimo.Sebaka pakeng tsa electrode le phala ke likhato tse 75.Ka mor'a hore arc e chese, arc e otlolloa bakeng sa ho futhumatsa pele.Ka mor'a hore lerotholi la pele la tšepe e qhibilihisitsoeng holim'a hlooho ea electrode le oela, electrode e romeloa.

Thempereichara ea letamo le qhibilihisitsoeng ka nako ena e lokela ho netefatsa hore boholo ba letamo le qhibilihisitsoeng ke bophara ba groove hammoho le hoo e ka bang 1 mm, e le hore thepa ea motheo e ka qhibiliha ka ho feletseng ka har'a lerotholi ho etsa weld.

Ts'ebetsong ea tjheseletsa ea sebele, hoa hlokahala ho ithuta ho boloka liphetoho tsa mocheso oa letamo le qhibilihisitsoeng le ho tseba mokhoa oa ho laola ka katleho mocheso oa letamo le qhibilihisitsoeng, e leng motheo oa ho ithuta theknoloji ea ho tjheseletsa.Hoa hlokahala ho khona ho ahlola lehlakoreng la tjheseletsa, boemo ba ho fepa le nako ea ho qhibiliha ho ea ka letamo le qhibilihisitsoeng la karolo e 'ngoe le e' ngoe, kapele ho utloisisa theknoloji ea ts'ebetso ea likarolo tse 'maloa tsa bohlokoa,' me ka mor'a nako ea koetliso ea sebele, boemo ba botekgeniki bo tla ntlafala. ka potlako, 'me sekhahla ketsahalo ea mefokolo tse fapa-fapaneng tjheseletsa Haholo ka tlaase ho moo, ho ntlafatsa bokgoni ba khatello ea kaho rarahaneng tjheseletsa, e leng ho loketseng ho ntlafatso ea theknoloji tjheseletsa nakong e tlang.

Nako ea poso: Jul-15-2021