Q1: Lintho tse chesehang ke eng?Ho kenyelletsa eng?

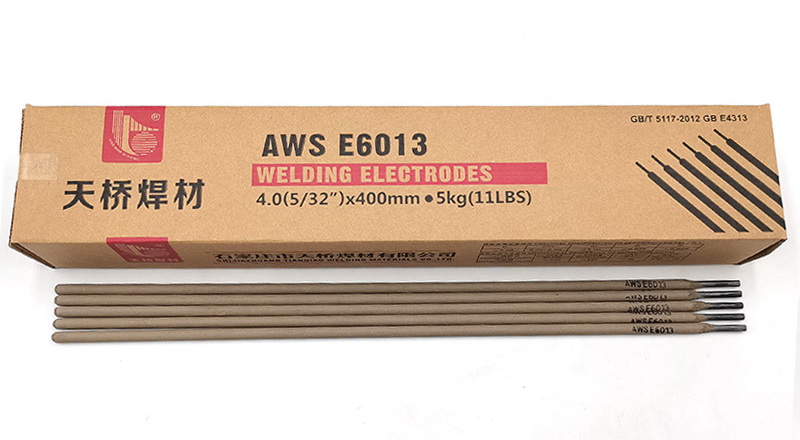

Karabo: Lisebelisoa tsa welding li kenyelletsa lithupa tsa welding, lithapo tsa welding, fluxes, likhase, li-electrode, li-gaskets, joalo-joalo.

Q2: Elektrode ea acid ke eng?

Karabo: Ho roala ha electrode ea acid ho na le li-oxide tse ngata tse kang SiO2, TiO2 le palo e itseng ea carbonate, 'me alkalinity ea slag e ka tlaase ho 1. Li-electrode tsa Titanium, li-electrode tsa calcium titanium, li-electrode tsa ilmenite le iron oxide. li-electrode kaofela ke li-electrode tsa acid.

Q3: electrode ea alkaline ke eng?

Karabo: Ho roala ha electrode ea alkaline ho na le lisebelisoa tse ngata tsa alkaline tse etsang slag tse kang marble, fluorite, joalo-joalo, 'me e na le tekanyo e itseng ea deoxidizer le alloying agent.Li-electrode tsa mofuta o tlase-hydrogen ke li-electrode tsa alkaline.

Q4: Electrode ea cellulose ke eng?

Karabo: Ho roala ha electrode ho na le lintho tse ngata tsa cellulose le arc e tsitsitseng.E senya le ho hlahisa khase e ngata ho sireletsa tšepe ea weld nakong ea ho cheselletsa.Mofuta ona oa elektrode o hlahisa slag e nyane haholo mme e bonolo ho e tlosa.E boetse e bitsoa eleketrode ea welding e theohileng tlase.E ka chesetsoa maemong ohle, 'me welding e otlolohileng e ka chesetsoa ho ea tlase.

Q5: Hobaneng ha electrode e tlameha ho omisoa ka thata pele ho tjheseletsa?

Melamu ea welding e atisa ho senya ts'ebetso ea ts'ebetso ka lebaka la ho kenngoa ha mongobo, ho fella ka arc e sa tsitsang, ho eketseha ha spatter, 'me ho bonolo ho hlahisa li-pores, mapetsong le liphoso tse ling.Ka hona, molamu oa welding o tlameha ho omisoa ka thata pele o sebelisoa.Ka kakaretso, mocheso oa ho omisa oa electrode ea acid ke 150-200 ℃, 'me nako ke hora e le 1;mocheso o omisang oa electrode ea alkaline ke 350-400 ℃, nako ke lihora tse 1-2, 'me e omisitsoe ebe e kenngoa ka incubator ka 100-150℃ Ka hare, e nke ha u ntse u tsamaea.

Q6: terata ea ho tjheseletsa ke eng?

Karabo: Ke terata ea tšepe e sebelisoang e le tšepe ea ho tlatsa nakong ea welding 'me e sebelisetsoa ho tsamaisa motlakase ka nako e le 'ngoe e bitsoang terata ea welding.Ho na le mefuta e 'meli: terata e tiileng le terata e nang le flux-cored.Ka tloaelo ho sebelisoa mohlala o tiileng oa terata: (GB-tekanyetso ea naha ea Chaena) ER50-6 (sehlopha: H08Mn2SiA).(AWS-American Standard) ER70-6.

Q7: Flux cored welding terata ke eng?

Karabo: Mofuta oa terata ea ho tjheseletsa e entsoeng ka likhoele tse tšesaane tsa tšepe tse phuthetsoeng liphaepheng tse chitja tsa tšepe 'me li tlatsitsoe ka phofo e itseng.

Q8: Ke hobane'ng ha terata ea flux cored e sirelelitsoe ke khase ea carbon dioxide?

Karabo: Ho na le mefuta e mene ea terata e nang le flux-cored wire: acidic flux-cored gas shielded welding terata (mofuta oa titanium), alkaline flux-cored gas shielded wire (mofuta oa titanium calcium), mofuta oa tšepe oa mofuta oa flux-cored gase o sirelelitsoeng terata. le terata ea tšubuhlellano ea flux-coreed self-shielded.Mohala oa lehae oa titanium flux-cored wire welding terata ka kakaretso o sirelelitsoe ke khase ea CO2;lithapo tse ling tsa tjheseletsa tse nang le flux-cored li sirelelitsoe ke khase e tsoakiloeng (ka kopo, sheba litlhaloso tsa terata ea flux-cored).Metallurgical reaction ea mofuta o mong le o mong oa slag oa khase e fapane, ka kopo u se ke ua sebelisa khase ea tšireletso e fosahetseng.Flux-cored welding wire gas slag tshireletso e kopaneng, sebopeho se setle sa seam, thepa e phahameng e pharalletseng ea mochini.

Q9: Hobaneng ho na le litlhoko tsa tekheniki bakeng sa bohloeki ba khase ea carbon dioxide?

Karabo: Ka kakaretso, khase ea CO2 ke sehlahisoa sa tlhahiso ea lik'hemik'hale, se nang le bohloeki bo ka bang 99.6% feela.E na le mesaletsa ea litšila le mongobo, e leng se tla tlisa mefokolo e kang li-pores ho weld.Bakeng sa lihlahisoa tsa bohlokoa tsa ho tjheseletsa, khase e nang le bohloeki ba CO2 ≥99.8% e tlameha ho khethoa, e nang le li-pores tse fokolang ka har'a weld, lihlahisoa tse tlaase tsa hydrogen, le khanyetso e ntle ea crack.

Q10: Hobaneng ho na le litlhoko tse phahameng tsa tekheniki bakeng sa bohloeki ba argon?

Karabo: Hona joale ho na le mefuta e meraro ea argon 'marakeng: argon e hlakileng (bohloeki bo pota-potileng 99.6%), argon e hloekileng (bohloeki bo pota-potileng 99.9%), le argon e hloekileng (bohloeki ba 99.99%).Tse peli tsa pele li ka chesetsoa ho tšepe ea carbon le tšepe e sa hloekang.argon e phahameng ea bohloeki e tlameha ho sebelisoa bakeng sa ho tjheseletsa litšepe tse se nang ferrous joalo ka aluminium le lialloi tsa aluminium, li-alloys tsa titanium le titanium;ho qoba oxidation ea weld le sebaka se amehileng ke mocheso, sebopeho sa boleng bo holimo le se setle ha se fumanehe.

Nako ea poso: Jun-23-2021