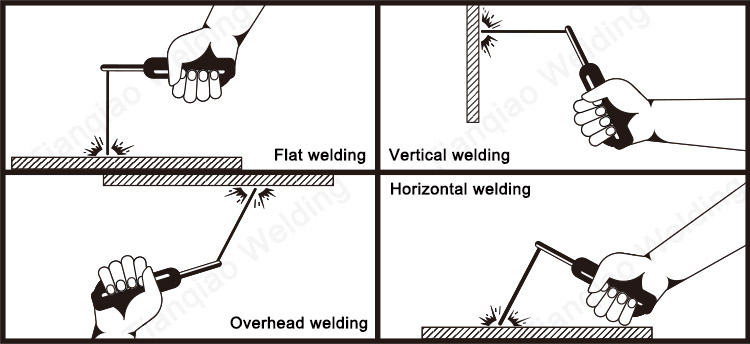

Boemo ba ho tjheseletsa bo boleloa ha ho tjheseletsa, boemo bo lekanyeditsweng ba sebaka sa weld ho welder.

Setšoantšo sa 1. Tianqiao welding positon

Setšoantšo sa 1. Tianqiao welding positon

Ho na le tjheseletso e bataletseng, welding e tshekaletseng, welding e otlolohileng le tjheseletso e hodima hlooho.Flat tjheseletsa e bua ka tjheseletsa tshekaletseng etsoa ke welder inamisa hlooho, kahoo e boetse e bitsoa downhand tjheseletsa;bakeng sa tjheseletsa kamanong e bōpehileng joaloka T, tjheseletsa e bōpehileng joaloka T e atisa ho behoa ho 45 ° ho theha boemo ba ho tjheseletsa ha seam se theohelang, se bitsoang ho tjheseletsa sekepe.Ho tjheseletsa ho tshekaletseng ho bolela ho tjheseletsa ho tshekaletseng ho etsoang ke setjhesetsi ka bolelele bo lekanang le ba letsoho.Ho tjheseletsa ka ho otloloha ho bolela ho tjheseletsa ho ya tlase ho ya hodimo ho ya hodimo ke setjheseletsa.Ho cheselletsa ka holim'a hlooho ho bolela ho tjheseletsa seam ho tshekaletseng ho etsoang ke motho ea shebileng holimo.Flat welding ke eona e bonolo ka ho fetesisa ea ho netefatsa boleng ba tjheseletsa, welding e otlolohileng ke ea bobeli, welding e otlolohileng ke ea boraro, 'me ho cheselletsa holimo ke eona e thata ka ho fetisisa ho netefatsa boleng mme e lokela ho qojoa ka hohle kamoo ho ka khonehang.

Setšoantšo sa 2. Tianqiao tjheseletsa sephara

Setšoantšo sa 2. Tianqiao tjheseletsa sephara

Ho cheseletsa sephara

Litšobotsi tsa welding tsa flat welding:

1. Tšepe ea weld haholo-holo e itšetlehile ka boima ba eona ho fetela ho letamo le qhibilihisitsoeng.

2. Sebopeho le tšepe ea letamo le entsoeng ka ho qhibilihisoa li bonolo ho boloka le ho laola.

3. Bakeng sa litšepe tse nang le litšepe tse nang le botenya bo tšoanang, hona joale ho cheselletsa sebakeng se bataletseng se seholo ho feta se libakeng tse ling, 'me katleho ea tlhahiso e phahame.

4. Letamo la li-slag le tse qhibilihisitsoeng li atisa ho kopanya, haholo-holo ha ho tjheseletsa li-welds flat fillet, slag e bonolo ho etella pele le ho theha ho kenngoa ha slag.

*Ha ho bonolo ho khetholla slag ea lere la ho cheselletsa acid ho letamo le qhibilihisitsoeng;lithupa tse peli tsa alkaline welding li batla li hlakile;tekanyetso ea HG20581 e bolela ka ho hlaka hore lithupa tsa ho cheselletsa acid li ke ke tsa sebelisoa likepeng tsa Sehlopha sa II le sa III.

5. Mekhahlelo le ts'ebetso e sa nepahalang ea tjheseletsa e ka lebisa habonolo mefokolong e kang weld bead, undercut, and welding deformation.

6. Ha lehlakoreng le ka morao la tjheseletsa le nang le lehlakore le le leng le thehoa ka bolokolohi, weld ea pele e na le mekhoa e sa tšoaneng ea ho kenella le ho bopa ho futsanehileng ka morao.

Lintlha tsa welding tsa flat welding:

1. Ho ea ka botenya ba poleiti, ho ka sebelisoa electrode e kholoanyane ea bophara le motlakase o moholoanyane oa welding.

2. Ha ho chesoa, molamu oa welding le weldment li etsa angle ea 60 ~ 80 °, 'me ho arohana ha slag le tšepe ea metsi ho laoloa ho thibela slag ho hlaha esale pele.

3. Ha botenya ba poleiti bo le tlase kapa bo lekana le 6mm, butt flat welding ka kakaretso e na le mofuta oa I groove, 'me seam se ka pele se lokela ho ba tjheseletsa e khuts'oane ea arc ka eleketrode ea φ3.2 ~ 4, le botebo ba ho kenella. fihla 2/3 ea botenya ba poleiti;pele mokokotlo o tiisitsoe, Ha ho hlokahale ho hloekisa metso (ntle le mehaho ea bohlokoa), empa slag e tlameha ho hloekisoa 'me hona joale e ka ba kholoanyane.

4. Haeba ho na le ho sa hlaka ho kopanya ha slag le tšepe ea letamo le qhibilihisitsoeng ka har'a butt flat welding, arc e ka lelefatsoa, electrode e ka sekamela pele, 'me slag e entsoeng ka ho qhibilihisoa e ka sutumelletsoa ka morao ho letamo le qhibilihisitsoeng ho thibela ho kenngoa ha slag.

5. Ha ho cheselletsa li-welds tse tšekaletseng, ho chesehela holimo ho lokela ho sebelisoa ho thibela ho kenngoa ha slag le letamo le qhibilihisitsoeng ho tsoela pele ho qoba ho kenngoa ha slag.

6. Ha u sebelisa li-welding tse ngata le li-pass-pass tse ngata, ela hloko palo ea li-welding tse fetang le tatellano ea li-welding, 'me lera le leng le le leng ha lea lokela ho feta 4 ~ 5mm.

7. Bakeng sa manonyeletso a nang le mahlakore a sephara a mofuta oa T, lenonyeletso la sekhutlo, le lenonyeletso le kopanang, haeba botenya ba lipoleiti tse peli bo fapane, angle ea molamu oa welding e lokela ho fetoloa ho khelosa arc ka lehlakoreng le leng la poleiti e teteaneng; e le hore lipoleiti tse peli li futhumale ka ho lekana.

8. Khetho e nepahetseng ea mokhoa oa ho romella

(1) Ha botenya ba tjheseletsa bo ka tlase ho kapa bo lekana le 6mm, mofuta oa I groove butt flat tjheseletsa.Ha ho tjheseletsa ka mahlakoreng a mabedi ho amohelwa, seam sa welding se ka pele se nka mola o otlolohileng, o leng butle hanyenyane;mokokotlo oa welding seam o boetse o nka mohala o otlolohileng, 'me hona joale oa welding o moholo hanyenyane., Kapele.

(2) Ha botenya ba poleiti bo le ≤6mm, ha ho buloa mefuta e meng ea li-grooves, ho ka sebelisoa welding ea multilayer kapa multilayer multi-pass welding.Mokhahlelo oa pele oa tjheseletsa o ka tlase o lokela ho sebelisa eleketrode e nyane ea hajoale, e nyane e tloaelehileng, mohala o otlolohileng kapa sawtooth.tjheseletsa bareng ya sebopeho sa sebopeho.Bakeng sa ho tlatsa welding ea layer, ho ka khethoa electrode e kholoanyane ea bophara le li-arc tse khutšoane tse nang le welding e kholo ea hona joale.

(3) Ha boholo ba leoto la tjheseletsa e bataletseng ea T-joint e ka tlase ho 6mm, ho ka sebelisoa welding e le 'ngoe,' me ho ka sebelisoa mokhoa oa lipalangoang, oblique kapa mokhoa oa lipalangoang oa zigzag;ha boholo ba leoto bo le kholoanyane, ho lokela ho sebelisoa welding ea multilayer kapa multilayer welding.Multi-pass welding, welding e tlase e sebelisa mokhoa oa ho tsamaisa linear strip, 'me lera la ho tlatsa le ka khetha lipalangoang tsa oblique sawtooth kapa oblique circular strip.

(4) Ka kakaretso, welding ea multilayer le multi-pass welding e lokela ho kenngoa ka mokhoa o otlolohileng oa lipalangoang.

Li-electrode tsa tšepe tse bonolo tse loketseng ho cheselletsa sephara liAWS E6013, AWS E6010, AWS E6011, AWS E7018.

Setšoantšo sa 3. Tianqiao welding e otlolohileng

Setšoantšo sa 3. Tianqiao welding e otlolohileng

Welding e otlolohileng

Litšobotsi tsa welding tsa vertical welding:

1. Letamo la tšepe le entsoeng ka tšepe e qhibilihisitsoeng le slag e qhibilihisitsoeng li oa ka lebaka la boima ba tsona 'me li bonolo ho li arola.

2. Ha mocheso oa letamo le entsoeng ka ho qhibilihisoa o phahame haholo, tšepe e qhibilihisitsoeng ea letamo e bonolo ho rotha fatše ho theha mefokolo e kang weld bead, undercut, slag inclusion, joalo-joalo, le weld ha e lekane.

3. Motso oa T-joint weld o bonolo ho theha ho kenella ho sa fellang.

4. Tekanyo ea ho kenella e bonolo ho e utloisisa.

5. Tlhahiso ea welding e tlase ho feta tjheseletsa e bataletseng.

Lintlha tse ka sehloohong tsa welding vertical:

1. Boloka angle e nepahetseng ea molamu oa welding;

2. Ha ho etsoa tlhahiso, welding e otlolohileng e sebelisoa hangata, 'me welding e otlolohileng e hloka lithupa tse khethehileng tsa welding ho netefatsa boleng ba weld.The tjheseletsa hona joale bakeng sa vertical up welding ke 10 ~ 15% e nyane ho feta ea ho tjheseletsa sephara, 'me bophara bo bonyenyane ba eleketrode (<φ4mm) bo lokela ho khethoa.

3. Sebelisa welding e khuts'oane ea arc ho khutsufatsa sebaka ho tloha marotholi ho ea letamong le qhibilihisitsoeng.

4. Sebelisa mokhoa o nepahetseng oa ho romella.

(1) T-groove butt joint (hangata e sebelisetsoa lipoleiti tse tšesaane) ha welding e otlolohileng e etsoa, ho sebelisoa linear, zigzag, crescent-shaped strip welding, 'me bolelele ba arc ha bo fete 6mm.

(2) Ha ho buloa mefuta e meng ea tšubuhlellano ea groove butt e otlolohileng, karolo ea pele ea weld hangata e chesetsoa ka tjheseletso e robehileng, e bōpehileng joaloka crescent le ea kgutlotharo e nang le motsuko o monyane.Hamorao, karolo e 'ngoe le e' ngoe e ka sebelisoa bakeng sa ho roala ha crescent kapa zigzag.

(3) Nakong ea tjheseletsa e otlolohileng ea manonyeletso a nang le sebopeho sa T, molamu oa ho tjheseletsa o lokela ho ba le nako e loketseng ea ho lula ka mahlakoreng ka bobeli le likhutlong tse kaholimo tsa seam, 'me bophahamo ba molamu oa tjheseletsa ha boa lokela ho ba kholo ho feta bophara ba tjheseletsa. seam.Ts'ebetso ea molamu oa welding e tšoana le ea li-welding tse ling tse otlolohileng tse nang le li-grooves.

(4) Ha ho chesetsoa lera la sekoahelo, sebopeho sa bokaholimo ba weld se khethoa ke mokhoa oa ho tsamaisa.Lithapa tse bōpehileng joaloka crescent li ka sebelisoa bakeng sa ho cheselletsa seam holim'a litlhoko tse phahameng;li-zigzag strips li ka sebelisoa bakeng sa libaka tse bataletseng (sebopeho sa concave bohareng se amana le nako ea khefu).

Li-electrode tsa tšepe tse bonolo tse loketseng bakeng sa ho tjheseletsa tse otlolohileng liAWS E6013, AWS E6010, AWS E6011, AWS E7018, haholoholoE6011e loketse bakeng sa welding ea holimo-tlase.

Setšoantšo sa 4. Tianqiao holim'a tjheseletsa

Welding ka holimo

Litšobotsi tsa welding tsa overhead welding:

1. Tšepe e qhibilihisitsoeng e oa ka lebaka la matla a khoheli, ’me sebōpeho le boholo ba letamo le entsoeng ka ho qhibilihisoa ha lia lokela ho laoloa.

2. Ho thata ho tsamaisa strip, 'me bokaholimo ba weldment ha bo loketse bakeng sa welding.

3. Litšitiso tse kang ho kenngoa ha slag, ho kenella ho sa phethoang, bead ea weld le sebopeho se futsanehileng sa weld ho bonolo ho hlaha.

4. Litšepe tse entsoeng ka ho qhibilihisoa lia phatloha ebe lia nama, e leng se ka bakang likotsi tse chesang habonolo.

5. Ho sebetsa hantle ha ho tjheseletsa ka holimo ho tlase ho feta ba maemo a mang.

Lintlha tsa welding tsa li-welding tse holimo:

1. Ho chesetsoa ka holimo ha litšepe tsa butt.Ha botenya ba weldment bo le tlase kapa bo lekana le 4mm, sebelisa li-grooves tsa mofuta oa I 'me u sebelise lithupa tsa welding tsa φ3.2mm tse nang le li-welding tse itekanetseng hona joale;ha botenya ba ho tjheseletsa bo le boholo ho feta kapa bo lekana le 5mm, ho lokela ho sebediswa tjheseletsa e nang le mesela e mengata le e mengata.

2. The tjheseletsa seam ea lenonyeletso e bōpehileng joaloka T ke ho cheseletsa holimo.Ha leoto la tjheseletsa le le ka tlase ho 8mm, ho lokela ho sebelisoa welding ea lera le le leng, 'me ha leoto la ho tjheseletsa le le leholo ho feta 8mm, ho lokela ho sebelisoa welding ea multilayer le multi-pass.

3. Ho latela maemo a ikhethileng, sebelisa mokhoa o nepahetseng oa ho tsamaisa thepa:

(1) Ha boholo ba leoto la tjheseletsa le le lenyenyane, ho sebelisoa mofuta o lekanang kapa oa linear ho tlatsa tjheseletsa ea lera le le leng;ha boholo ba leoto la ho tjheseletsa le le leholo, ho ka sebelisoa tjheseletsa e nang le li-multi-layer kapa multi-layer multi-pass welding, 'me karolo ea pele e lokela ho sebelisoa Lipalangoang tse otlolohileng, likarolo tse ling li ka khetha mokhoa oa ho tsamaisa lesale la oblique kapa mokhoa oa ho tsamaisa lesale la oblique.

(2) Ho sa tsotellehe hore na ke mofuta ofe oa mokhoa oa lipalangoang o amoheloang, tšepe ea weld ha ea lokela ho ba ngata haholo nako le nako ha e fetela letamong le entsoeng ka ho qhibilihisoa.

Li-electrode tsa tšepe tse bonolo tse loketseng ho cheselletsa holimo liAWS E6013, AWS E6010, AWS E6011, AWS E7018

Setšoantšo sa 5. Tianqiao tjheseletsa tshekaletseng

Setšoantšo sa 5. Tianqiao tjheseletsa tshekaletseng

Ho tjheseletsa ho tshekaletseng

Litšobotsi tsa welding tsa welding e otlolohileng:

1. Tšepe e entsoeng ka ho qhibilihisoa e oela habonolo holim'a groove ka lebaka la boima ba eona, e bakang mefokolo e ka tlaase ho lehlakoreng le ka holimo, le sefaha sa weld se bōpehileng joaloka teardrop kapa mefokolo e sa fellang ea ho kena ka lehlakoreng le ka tlaase.

2. Litšepe tse qhibilihisitsoeng le slag li bonolo ho arola, li batla li tšoana le welding e otlolohileng.

Lintlha tsa bohlokoa tsa welding e otlolohileng:

1. Lithako tse tšekaletseng tsa butt tse tšekaletseng li na le sebopeho sa V kapa se bōpehileng joaloka K, manonyeletso a marako a nang le botenya ba 3 ~ 4mm a ka chesetsoa ka mahlakoreng ka bobeli ka mefuta ea mofuta oa I.

2. Sebelisa molamu o monyenyane oa ho tjheseletsa ka bophara, hona joale oa welding o monyenyane ho feta ho tjheseletsa sephara, ts'ebetso e khutšoanyane ea arc, e ka laola hantle ho phalla ha tšepe e qhibilihisitsoeng.

3. Ha o tjheseletsa lipoleiti tse teteaneng, ho phaella ho weld e ka tlase, ho eletsoa ho sebelisa welding ea multilayer le multi-pass welding.

4. Bakeng sa welding ea multilayer le multi-pass welding, tlhokomelo e khethehileng e lokela ho lefshoa ho laola sebaka se fetang pakeng tsa li-weld pass.Bakeng sa tjheseletsa e 'ngoe le e 'ngoe e fetang, qala ho tjheseletsa ho 1/3 ea weld e fetileng ho thibela ho se lekane.

5. Ho ea ka boemo bo itseng, boloka lehlakoreng le nepahetseng la molamu oa welding, 'me lebelo la welding le lokela ho ba le thibelang hanyenyane le ho lekana.

6. Sebelisa mokhoa o nepahetseng oa ho romella.

(1) Bakeng sa tjheseletsa e otlolohileng ea Type I butt, ho molemo ho sebelisa mokhoa o lumellanang oa linear strip bakeng sa seam se ka pele sa welding;likhoele tse chitja tse otlolohileng kapa tse nyane li lokela ho sebelisoa bakeng sa likarolo tse teteaneng, le likhoele tse otlolohileng ka lehlakoreng le ka morao, 'me hona joale oa welding o ka eketsoa ka nepo.

(2) Sebelisa litšepe tse ling tse tšekaletseng tsa bevel butt.Ha lekhalo le le nyane, welding e tlase e ka sebelisa likhoele tse otlolohileng;ha lekhalo le le leholo, lera le ka tlase le nka li-striprocating linear strips;ha likarolo tse ling e le li-welding tse ngata, lesela le sekametseng le ka sebelisoa.Lipalangoang tse otlolohileng li lokela ho sebelisoa bakeng sa lipalangoang tse chitja tsa li-strip le li-welding tse ngata le tse ngata.

Li-electrode tsa tšepe tse bonolo tse loketseng bakeng sa ho cheselletsa tse rapameng liAWS E6013, AWS E6010, AWS E6011, AWS E7018

Nako ea poso: Jul-21-2021